Due to their compact size and excellent flexibility, fiber optic sensors can be easily installed in confined spaces. However, when the bending radius of the fiber optic sensor is too small, the optical signal suffers loss, which adversely affects the accuracy of the sensor measurements.

In many practical applications, it is often difficult to avoid situations where the fiber optic sensor must be bent to a small radius during installation. Therefore, effectively addressing the issue of signal loss due to fiber bending has become a focal point in the industry.

Next, let's discuss the potential adverse effects of bending on standard fiber optics and how bend-insensitive fiber optics operate under small bending radii.

Why can't fiber optic cables be excessively bent?

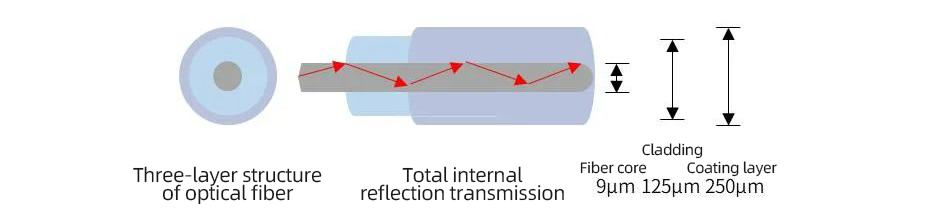

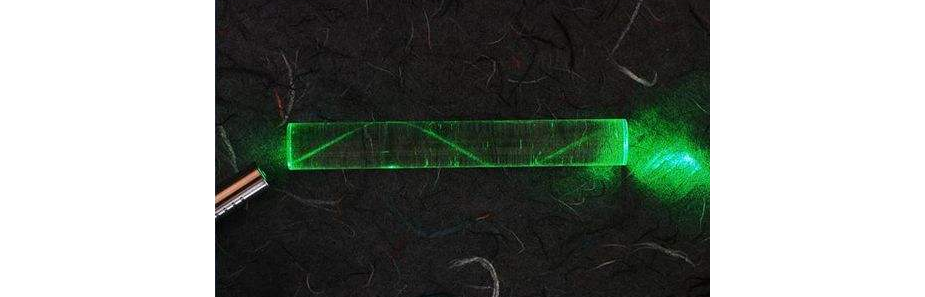

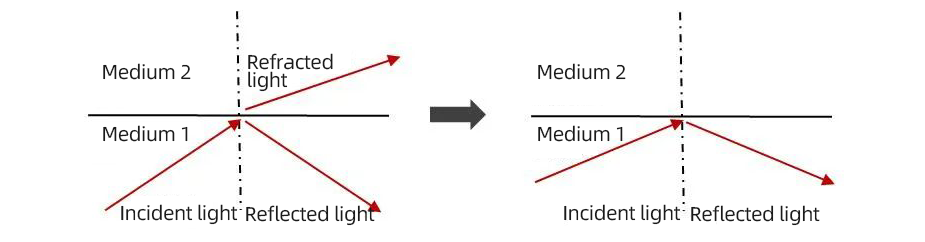

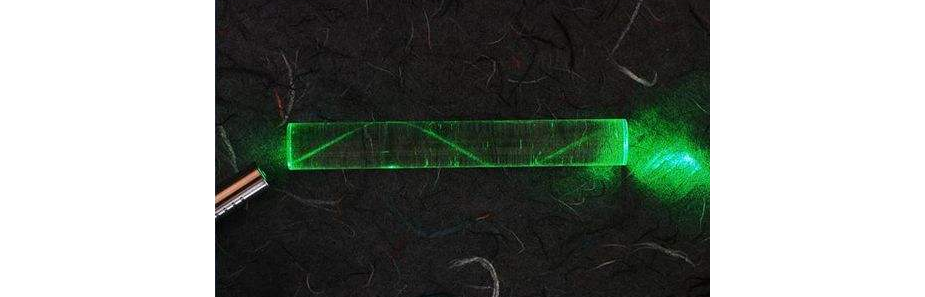

When light transitions from one medium to another, refraction and reflection occur at the interface between the two media. As the angle of incidence, the angle between the light ray and the interface, increases, the reflected light gradually intensifies, while the refracted light diminishes. When the angle of incidence reaches a certain critical value, the refracted light completely vanishes, leaving only the reflected light. This phenomenon is known as total internal reflection.

Generally, standard single-mode fiber maintains a low loss coefficient of about 0.2dB/km at a wavelength of 1550nm, demonstrating excellent transmission performance. However, when the fiber is bent, whether through macroscopic large bends or microscopic small bends, it can negatively impact light transmission. In such cases, the conditions for total internal reflection within the fiber may no longer be met, causing some light signals to leak into the cladding. This leakage not only reduces the optical power but also directly increases transmission loss, thereby affecting the quality and efficiency of fiber optic communication. Therefore, during the installation and use of fiber optics, it is crucial to avoid excessive bending to ensure stable and efficient signal transmission.

How to Effectively Reduce Bending Loss

Introduction to Bend-Insensitive Fiber Optics

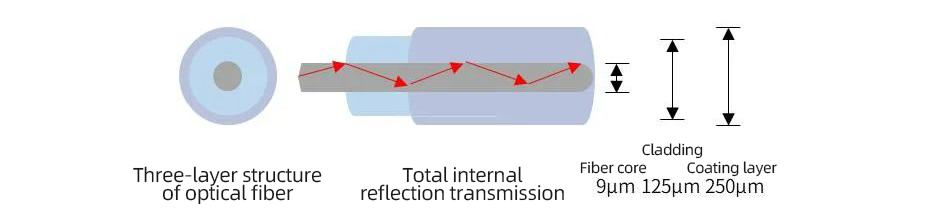

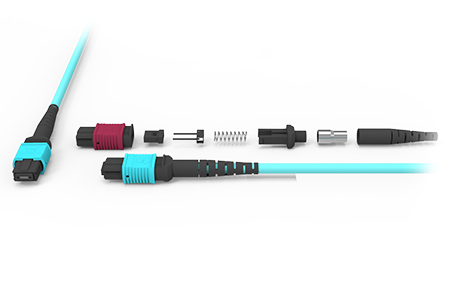

The structure of fiber optics is intricate and unique, consisting of three layers: the core, the cladding, and the coating. Each of these layers serves different functions, working together to ensure the stable transmission of light signals within the fiber.

Generally, standard single-mode fiber maintains a low loss coefficient of about 0.2dB/km at a wavelength of 1550nm, demonstrating excellent transmission performance. However, when the fiber is bent, whether through macroscopic large bends or microscopic small bends, it can negatively impact light transmission. In such cases, the conditions for total internal reflection within the fiber may no longer be met, causing some light signals to leak into the cladding. This leakage not only reduces the optical power but also directly increases transmission loss, thereby affecting the quality and efficiency of fiber optic communication. Therefore, during the installation and use of fiber optics, it is crucial to avoid excessive bending to ensure stable and efficient signal transmission.

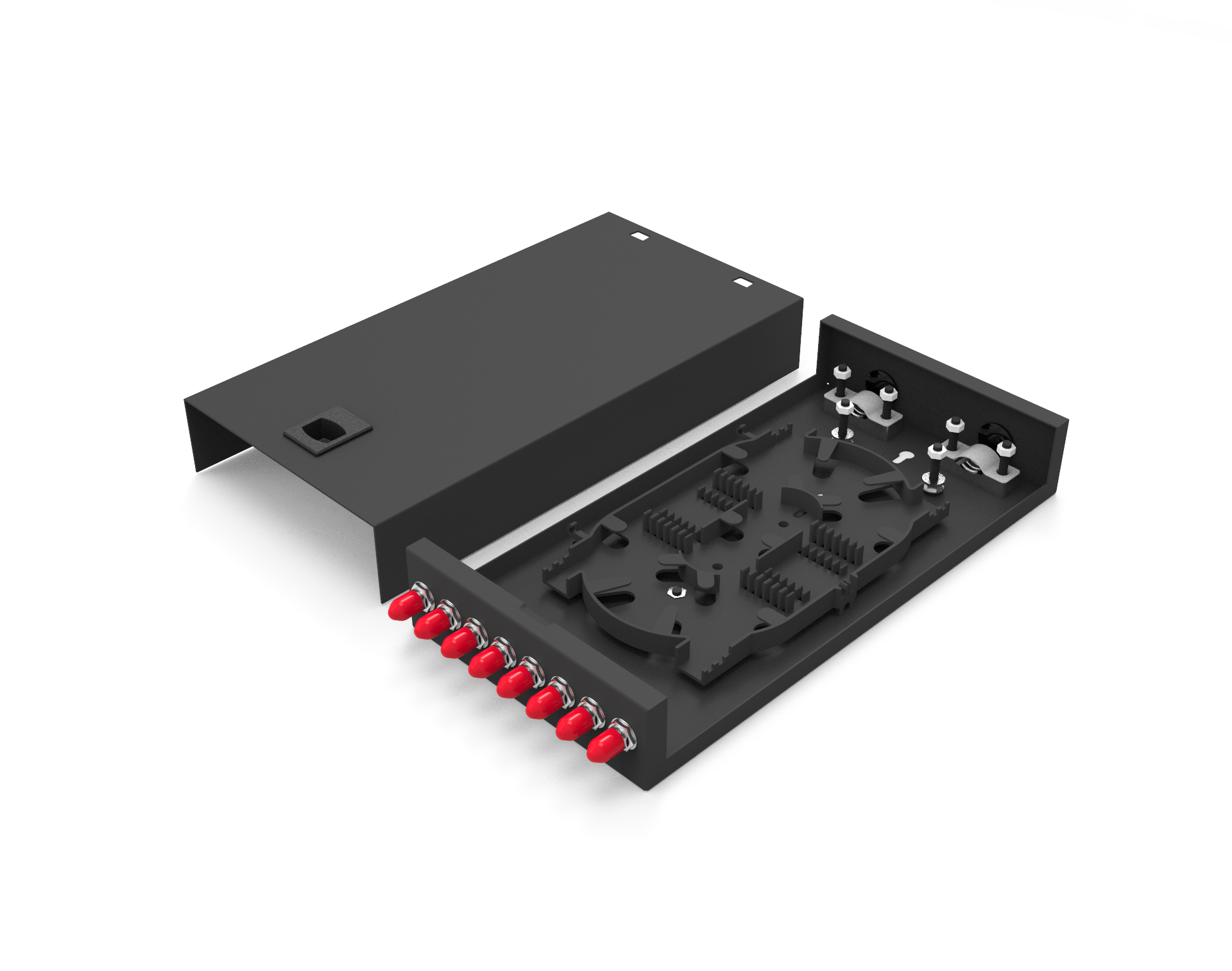

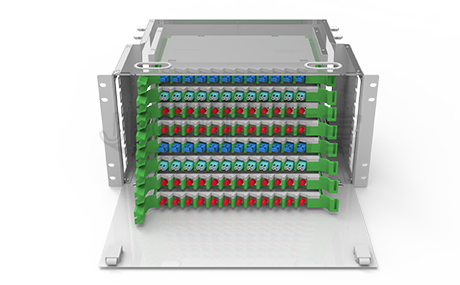

During the installation and layout of fiber optic links, fibers may experience significant bends at certain local points, especially at connectors and turns. Such bends are one of the main causes of link loss. Fortunately, this bending loss is reversible; by increasing the bending radius of the fiber, we can significantly improve the link loss situation.

So, how does light propagate within a fiber? Light does not travel in a straight line within the fiber but follows a certain path. Understanding this is crucial for optimizing fiber layout and reducing bending loss.

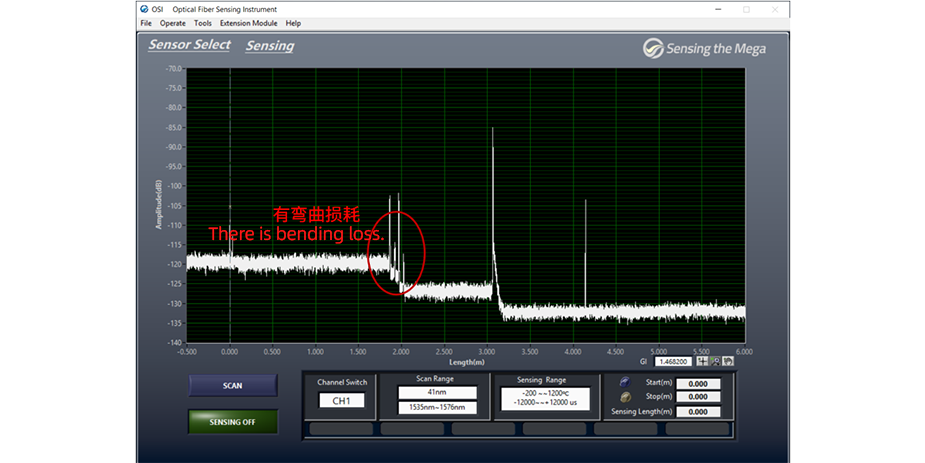

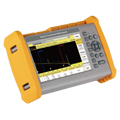

To more accurately locate and reduce bending loss, we can use Optical Frequency Domain Reflectometry (OFDR) equipment to measure the fiber link. OFDR can generate a distribution curve (distance vs. intensity/reflectance), which clearly reflects the loss situation at various points along the fiber link. Loss typically appears as steps on the curve, allowing us to intuitively identify and adjust the positions where loss occurs.

In addition to adjusting the fiber layout, we can opt to use bend-insensitive fibers as sensors. These fibers have a higher tolerance for smaller bending radii. For instance, the minimum bending radius for high-temperature strain single-mode fibers (model: PI125) is about 5mm, while the minimum bending radius for tight-buffered strain sensing cables (model: SS-0.9mm) is about 8mm.

Standard single-mode fiber (G.652 type) requires careful handling when bent. To ensure stable light signal transmission, we recommend a bending radius greater than 5mm (diameter of 1cm). If the bending radius is too small, the light signal will suffer significant loss, which can reduce the signal-to-noise ratio of sensing measurements and potentially destabilize the measurement results. For selecting the minimum bending radius, we follow a rule of thumb: for long-term applications, the bending radius should be more than 150 times the cladding diameter of the fiber; for short-term applications, it should be more than 100 times the cladding diameter. Given that the cladding diameter of standard single-mode fiber is 125μm, this means the minimum bending radius should be 19mm for long-term applications and 13mm for short-term applications.

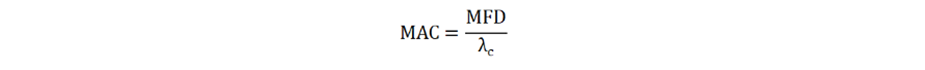

What are mode field diameter and cutoff wavelength? These are two important parameters in fiber optic communication, crucial for understanding fiber performance.

Bend-insensitive fiber (G.657 type), through optimized structural design, significantly improves its resistance to bending. To accurately evaluate the bending sensitivity of fiber optics, the industry commonly uses the MAC value as an indicator. The excellent performance of bend-insensitive fiber allows it to maintain efficient and stable light signal transmission in various bending environments, providing broader application prospects for fiber optic communication.

The MAC value is a key indicator for measuring the bend sensitivity of near step-index optical fibers. It represents the ratio of the mode field diameter to the cutoff wavelength. A decrease in the MAC value indicates reduced bend sensitivity, thereby enhancing the performance stability of the fiber in bending scenarios.

To design bend-insensitive fiber, we primarily adopt the following strategies:

reducing the mode field diameter, increasing the cutoff wavelength, or implementing both measures simultaneously. Specifically, we can reduce the core diameter or increase the core refractive index to decrease the mode field diameter, thereby improving the control of light transmission within the fiber. Additionally, reducing the cladding diameter of the fiber is an effective method. The market already offers bend-insensitive fibers with diameters reduced from the traditional 125 microns to 80 microns, and even fibers with outer diameters of 60 microns. Another strategy involves adding a low-refractive-index trench around the cladding, which has a similar effect to increasing the core refractive index, aiding in better control of light propagation within the core.

reducing the mode field diameter, increasing the cutoff wavelength, or implementing both measures simultaneously. Specifically, we can reduce the core diameter or increase the core refractive index to decrease the mode field diameter, thereby improving the control of light transmission within the fiber. Additionally, reducing the cladding diameter of the fiber is an effective method. The market already offers bend-insensitive fibers with diameters reduced from the traditional 125 microns to 80 microns, and even fibers with outer diameters of 60 microns. Another strategy involves adding a low-refractive-index trench around the cladding, which has a similar effect to increasing the core refractive index, aiding in better control of light propagation within the core.

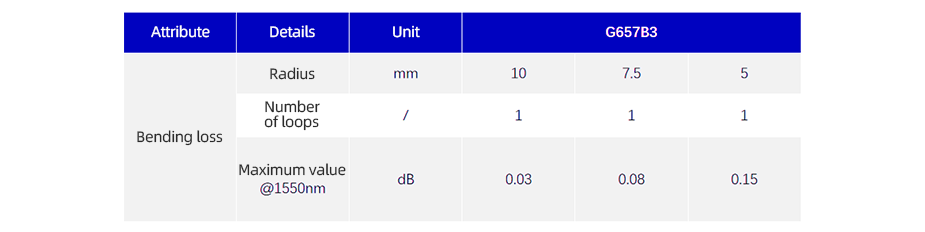

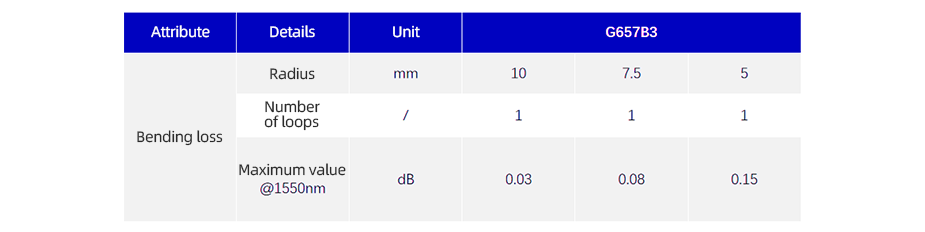

Through these methods, we can effectively mitigate the impact of fiber bending in sensing measurements, ensuring that the light signal can still be transmitted stably and efficiently in bent fibers. One commonly used type of bend-insensitive fiber on the market is G.657B3. The specific parameters for its bending radius and bending loss are shown in the table, which you can refer to when selecting fibers.

Ann

Ann