In the field of optical communication, SFP, SFP+, and XFP optical modules are three common interface modules, each with unique characteristics and applications. This article will provide a detailed analysis of the main differences between these three optical modules to help readers better understand and choose the most suitable optical module for their needs.

Introduction to SFP Optical Modules

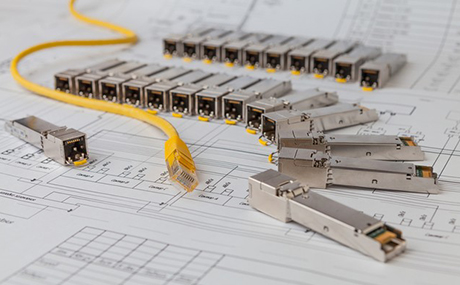

SFP, short for Small Form Pluggable, can be seen as an evolution of the GBIC. Compared to GBIC modules, SFP modules have significantly reduced dimensions, being only half the size of the latter. This compact design allows for more than twice the number of ports to be configured on the same panel, greatly increasing port density. Despite the reduction in size, SFP modules maintain a high degree of consistency with GBIC modules in terms of functionality, ensuring stability and reliability in network applications.

Some switch manufacturers, to facilitate user understanding, affectionately refer to SFP modules as mini-GBIC. This type of SFP module achieves a significant reduction in size, with its volume reduced by half compared to traditional GBIC modules. This means that on the same panel, we can configure more than twice the number of ports, greatly increasing device port density and transmission efficiency.

Although there are changes in size, SFP modules maintain a high degree of consistency with GBIC modules in terms of functionality. They both serve as interface devices that convert gigabit electrical signals into optical signals, ensuring stable and efficient data transmission in the network.

It is worth mentioning that GBIC supports hot-swappable functionality in design, making maintenance and upgrades more convenient for equipment. Additionally, as an internationally standardized interchangeable product, GBIC holds a considerable market share, offering users more choices and convenience.

Gigabit switches designed with GBIC interfaces are also popular in the market, with their flexibility and reliability widely recognized by users.

GBIC modules can mainly be divided into two categories:

One type is the conventional GBIC modules used for cascading, mainly for normal connections with other switches to ensure smooth communication in the network.

The other type is designed specifically for stacking GBIC modules, which are used for redundant connections with other switches to improve network reliability and stability.

Meanwhile, SFP modules achieve further size reduction and power consumption reduction by optimizing internal design and moving CDR and electrical dispersion compensation outside the module.

1.Standardization of SFP

The specification of SFP transceivers is developed by a multi-vendor consortium called the Multisource Agreement (MSA). It inherits the essence of the GBIC interface in design and allows for higher-density transceivers to be configured on the edge of the motherboard. Therefore, SFP is also affectionately referred to as "mini-GBIC" in the industry. It's worth noting that while SFF transceivers are smaller in size compared to SFP, they are soldered onto the motherboard in pin form rather than inserted into edge card slots like SFP.

2.Diversity of SFP Types

SFP transceivers offer a wide range of options for transmission and reception types. Users can choose the appropriate transceiver based on actual needs and fiber types (such as multimode or single mode) to achieve the best optical performance. Common optical SFP modules include: 850nm wavelength/550m distance MMF (SX) modules for short-distance communication, and 1310nm wavelength/10km distance SMF (LX) modules for long-distance communication. In addition, SFP transceivers also support copper cable interfaces, allowing host devices originally designed for fiber optic communication to easily connect to UTP network cables. Moreover, there are SFP modules on the market that support coarse wavelength division multiplexing (CWDM) and single-fiber "bi-directional" communication.

3.Classification and Application of Fibers

Fibers are mainly divided into multimode fibers and single-mode fibers. Multimode fibers are widely used in short-distance communication due to lower transmitter costs and easier construction. Among them, the 62.5um core diameter multimode fiber is more common, but it performs slightly worse than the 50um core diameter fiber. Single-mode fibers are more suitable for long-distance communication, with a core diameter of 9um and transmission distances of up to 10km, 20km, 70km, or even 120km. Switch manufacturers typically offer single-mode fiber products in 10km and 70km models, while the 20km model can effectively reduce the overall cost of specific network schemes. The 120km model is designed for special ultra-long operating environments.

4.Features and Differences of SFP

SFP optical modules typically use dual LC interface design, while there are also single-core SFP optical modules available. In terms of rate and fiber type, SFP can be divided into four types: 100Mbps single-mode multimode and 1Gbps single-mode multimode, meeting the communication needs of different scenarios.

Differences Between SFP Multimode and Single-mode

Differences Between SFP Multimode and Single-mode

When it comes to multimode and single-mode SFPs, firstly, their wavelengths differ. The wavelength of multimode SFPs is typically 850nm, with a transmission distance limited to below 2km, while single-mode SFPs have wavelengths of 1310nm or 1550nm, with transmission distances that can exceed 2km. It's worth mentioning that SFPs with these three wavelengths are more affordable compared to others.

In practical operations, the lack of markings on bare modules often leads to confusion. To address this issue, manufacturers typically differentiate them by the color of the bail. For example, a black bail usually represents multimode SFPs with a wavelength of 850nm, while blue, yellow, and purple bails represent single-mode SFPs with different wavelengths.

Let's take a closer look at the characteristics of multimode SFPs. The size of multimode fibers is usually 50/125μm or 62.5/125μm, with a bandwidth ranging from approximately 200MHz to 2GHz. Multimode transceivers use light-emitting diodes (LEDs) or lasers as light sources and achieve transmission distances of up to 2 kilometers through multimode fibers. The bail or outer color of such SFPs is typically black.

In contrast, single-mode SFPs have unique advantages. Their fiber size is 9/125μm, with nearly unlimited bandwidth and lower loss. Single-mode transceivers are commonly used for long-distance transmission, with transmission distances sometimes reaching an astonishing 100 kilometers. They use laser diodes (LDs) or LEDs with narrower spectral lines as light sources, and the bail or outer color of such SFPs is typically blue, yellow, or purple.

Distinguishing and Relating Analysis:

Single-mode fiber is favored in the market due to its relatively lower price, however, the price of single-mode equipment is much higher than that of similar multimode equipment. It's worth noting that single-mode equipment can operate not only on single-mode fiber but also be compatible with multimode fiber. In contrast, multimode equipment is only suitable for multimode fiber.

In recent years, as the technological gap between single-mode and multimode SFP transceivers has narrowed, the adoption of single-mode cables and modules has gradually become the mainstream choice in the industry. In practical applications, single-mode performance significantly outperforms multimode types.

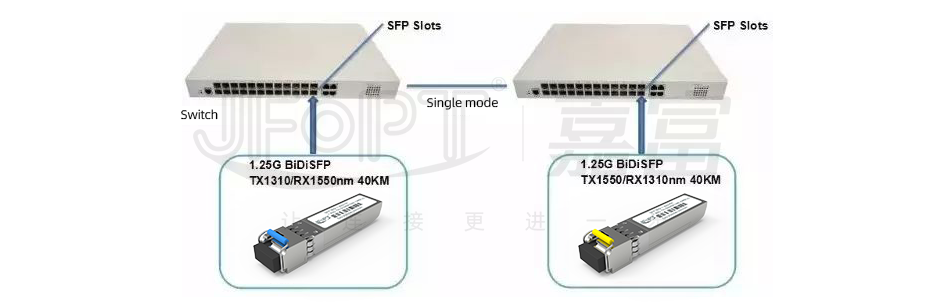

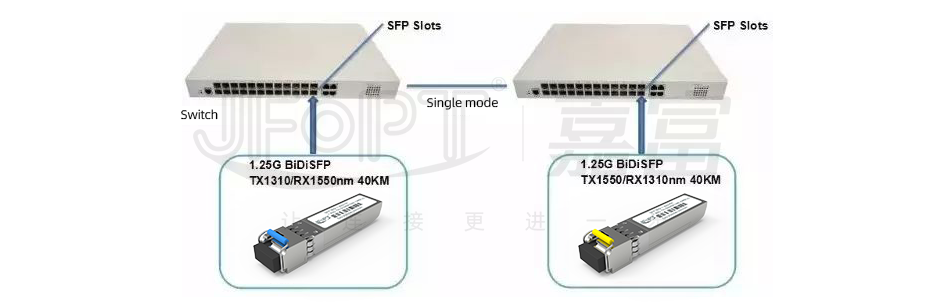

Difference Between SFP and BiDi SFP:

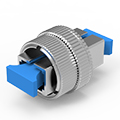

Common SFP modules have two ports, where the TX port is responsible for transmitting signals, and the RX port is responsible for receiving signals. However, BiDi SFP modules break this conventional design by having only one port. This single port, through the use of overall WDM coupler technology, achieves both signal transmission and reception functions on a single fiber, thereby demonstrating its unique technical advantages.

Connection Methods of SFP and BiDi SFP:

When using SFP modules, there is an important principle to follow: all SFP modules must be used in pairs. For common SFP modules, the key to the connection is to ensure that the SFPs at both ends have the same wavelength. For example, if we use an 850nm SFP on one end, then on the other end, we must also use an 850nm SFP to ensure smooth signal transmission (as shown in the diagram).

For BiDi SFP modules, due to their unique signal processing method—using different wavelengths to transmit and receive signals separately, it is essential to ensure that BiDi SFPs at both ends have opposite wavelengths when connecting. Specifically, if we use a TX1310/RX1550nm BiDi SFP on one end, then on the other end, we should select a TX1550/RX1310nm BiDi SFP to pair with it (as illustrated in the diagram).

Applications of SFP BiDi:

Currently, BiDi SFP modules play a crucial role in point-to-point (P2P) connections in Fiber-to-the-Home (FTTH) and Fiber-to-the-Building (FTTB) deployments. When building active Ethernet networks, they effectively connect Central Offices (CO) with Customer Premises Equipment (CPE). What makes BiDi SFP unique is its ability to utilize wavelength division multiplexing (WDM) technology, enabling bidirectional communication on a single fiber. This characteristic greatly simplifies the connection process between CO and CPE, enhancing communication efficiency and reliability.

Analysis of Differences between SFP, SFP+, and XFP:

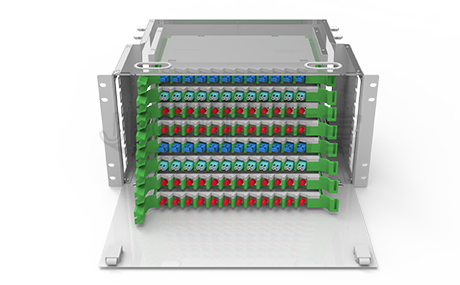

Many people find it confusing to differentiate between SFP+, SFP, and XFP, which can sometimes lead to unnecessary complications. The development of 10G modules has gone through several stages from 300Pin, XENPAK, X2 to XFP, ultimately achieving 10G signal transmission in the same size as SFP, leading to the birth of SFP+. With advantages such as miniaturization and low cost, SFP+ meets the demand for high-density optical modules in devices and has gradually replaced XFP, becoming the mainstream choice in the 10G market.

Specifically, SFP is a hot-pluggable small form-factor module, with a maximum speed of up to 4G, and commonly utilizes LC interfaces. SFP+, on the other hand, is a standard form-factor with a working speed of up to 10G, fully meeting the application requirements of Ethernet 10G.

As for XFP, it represents a standardized package for serial 10G optical transceivers.

Advantages of SFP+ Optical Modules:

Compact Size: SFP+ has the same form factor as SFP but is more compact than X2 and XFP, making it suitable for high-density deployments.

Strong Compatibility: SFP+ can directly connect with the same type of XFP, X2, and XENPAK modules, enhancing the flexibility of network construction.

Cost-effectiveness: Compared to XFP, X2, and XENPAK products, SFP+ has lower costs, helping to reduce the overall network construction expenses.

Differences between SFP and SFP+:

Form Factor: Both SFP and SFP+ have the same compact form factor.

Speed Difference: The maximum speed of SFP is up to 4G, while SFP+ supports speeds of up to 10G, meeting higher bandwidth demands.

Protocol Specifications: SFP follows IEEE 802.3 and SFF-8472 protocol specifications, while SFP+ supports digital diagnostic functions, providing richer management options.

Differences between SFP+ and XFP:

Speed and Interoperability: Both SFP+ and XFP are 10G fiber modules and can interoperate with other types of 10G modules, ensuring network connection diversity.

Form Factor: SFP+ is smaller in form factor compared to XFP, making it more suitable for space-limited environments.

Function Integration: Due to its smaller size, SFP+ integrates some functions such as signal modulation, serializer/deserializer, MAC, clock and data recovery (CDR), and electronic dispersion compensation (EDC) from the module to the motherboard card, achieving more efficient integration.

Protocol Compliance: XFP follows the XFP MSA protocol, while SFP+ follows IEEE 802.3ae, SFF-8431, SFF-8432, and other protocol specifications, ensuring wide compatibility and stability.

Market Acceptance: Currently, SFP+ has become a more mainstream design choice and is widely used in various types of network equipment.

BiDi SFP+ Optical Module: A New Choice for Cable Fault Handling

BiDi SFP+ Optical Module: A New Choice for Cable Fault Handling

With the rapid advancement of communication technology, the demand for wireless bandwidth in the market is increasing. To meet this market demand, numerous manufacturers of optical communication products are constantly innovating. Among them, the BiDi SFP+ optical module is an innovative product in this context. Let's explore the applications and advantages of BiDi SFP+ optical modules together.

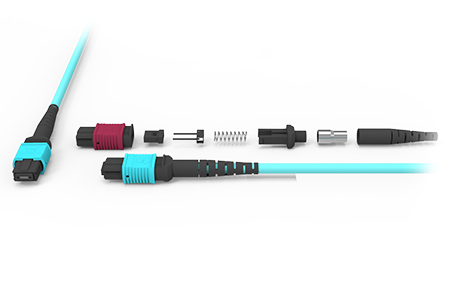

BiDi, short for Bidirectional, means two-way. The BiDi SFP+ optical module stands out with its unique single-fiber bidirectional design. It has only one port and achieves optical signal filtering through built-in filters, while being able to transmit 1310nm optical signals and receive 1550nm optical signals, or vice versa.

Due to this special design, BiDi SFP+ optical modules must be used in pairs, and their greatest advantage lies in saving fiber resources. In practical applications, common wavelength combinations for BiDi optical modules include TX1310/RX1550nm, TX1310/RX1490nm, and TX1550/RX1490nm, which can meet communication needs in different scenarios.

SFP+ optical module, short for 10 Gigabit Small Form Factor Pluggable, is a hot-pluggable optical transceiver independent of communication protocols. It typically supports optical wavelengths of 850nm, 1310nm, and 1550nm, widely applicable in 10G bps SONET/SDH, fiber channel, gigabit Ethernet, 10 gigabit Ethernet, and even DWDM links.

The development of BiDi SFP+ optical modules is based on the CPRI (Common Public Radio Interface) and OBSAI (Open Base Station Architecture Initiative) standards, ensuring outstanding performance in the wireless communication field. This module adopts the SFP+ small form factor, meeting protocols such as SFF-8431 MSA, SFF-8432, and SFF-8472, and supports single-fiber bidirectional transmission for efficient fiber utilization. Additionally, BiDi SFP+ optical modules support various transmission distances, such as 10km, 20km, and 40km, meeting communication needs in different scenarios.

It is worth mentioning that BiDi SFP+ optical modules have a wide operating temperature range, from 0°C to 75°C, making them an ideal choice for indoor and outdoor communication networks. They provide high-speed, stable signal transmission channels for networks, ensuring reliable data transmission.

In summary, BiDi SFP+ optical modules have several advantageous features:

Transmission distances of up to 10KM, 20KM, 40KM, and 60KM with TX1270/RX1330nm wavelengths; and up to 80KM with TX1490/RX1550nm wavelengths.

Single power supply +3.3V, simple and efficient.

Support for LVPECL/PECL data interfaces, providing rich data interaction options.

Operating temperature range of 0°C to 70°C, adaptable to various environments.

Compliance with GR-468-CORE requirements, ensuring product quality and performance.

Compliance with Laser Class 1 standards, meeting IEC60825-1 requirements, safe and reliable.

Providing products compliant with RoHS specifications, meeting environmental standards.

In the field of wireless communication, BiDi SFP+ optical modules have become an indispensable part of both existing and newly constructed wireless communication base stations, thanks to their outstanding performance and wide-ranging applications. These modules not only establish a high-speed, stable signal transmission bridge between communication base stations and fiber antennas but also earn widespread market recognition for their excellent transmission efficiency and stability.

The Importance and Procedure of Aging Testing for SFP Modules

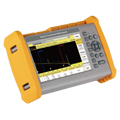

Quality is the cornerstone of any product's market presence. To ensure that SFP modules meet the highest standards of quality, we employ a series of rigorous testing measures, including incoming inspection, product parameter testing, distance testing, switch testing, and the crucial aging test. A. Purpose of Aging Testing:

A. Purpose of Aging Testing:

Fault Prediction: Identify potential faulty products in advance through aging testing before shipment to avoid unnecessary trouble for customers.

Quality Control: Ensure that fault-free products leave the factory to maintain brand reputation and enhance customer satisfaction.

Waste Reduction: Effectively reduce the rate of defective products, minimize resource wastage, and improve production efficiency.

Stability Assurance: Ensure that products can operate stably under various environments after leaving the factory, providing customers with lasting and reliable services.

B. Procedure of Aging Testing:

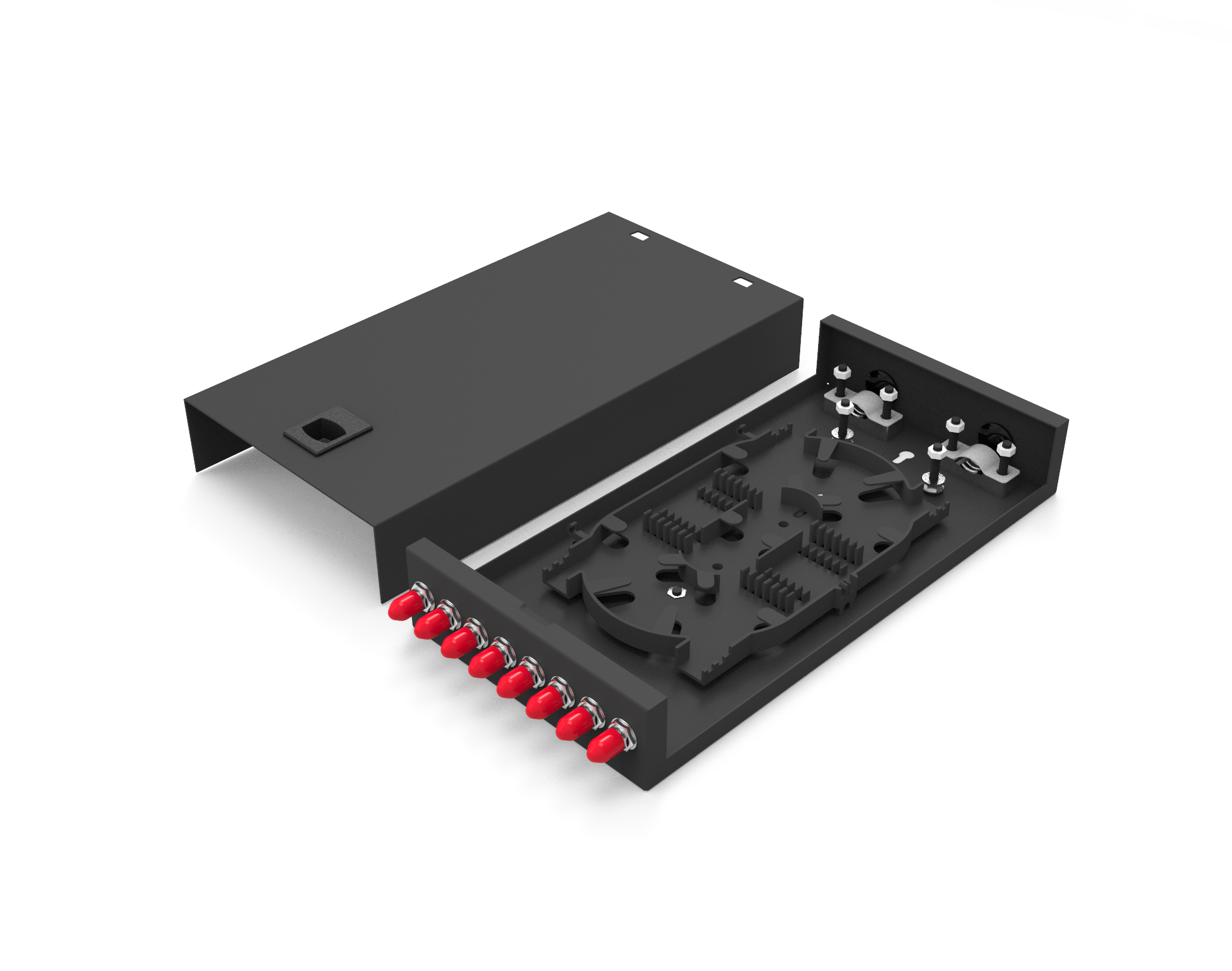

Module Installation: First, accurately install the SFP module onto the aging board to ensure a stable connection.

Power Preparation: Power on to provide stable power supply for the module.

Connect Male and Female Plugs: Correctly connect the male and female plugs to ensure smooth signal transmission.

Start Aging Machine: Turn on the aging machine switch to start the aging test program.

Close the Machine Door: Close the aging machine door to ensure the sealed environment of the test.

Set Parameters: Click to run on the display screen and set the temperature to 75°C and humidity to 0% to simulate extreme working conditions.

Aging Operation: Allow the module to undergo continuous aging testing in the set environment for approximately 24 hours.

Module Placement: After the aging test is completed, neatly arrange the modules for subsequent testing.

Transmit and Receive Testing: Finally, perform transmit and receive testing on the modules to ensure their performance meets factory standards.

Ann

Ann