In the process of constructing an efficient and stable fiber optic network, adhering to rigorous cabling installation standards is crucial. These standards not only ensure the excellent performance of the fiber optics but also form the foundation of high-quality network construction. The following are the key steps to achieving high-quality fiber optics, providing clear guidance for your fiber optic cabling installation. These steps include design planning, preparation work, cable installation, splicing and testing. We will discuss the importance of each step and offer some practical advice to help ensure a high-quality fiber optic network.

1. Design Planning

Before initiating fiber optic cabling installation, thorough design planning is an indispensable step. In this process, we first need to clarify the specific requirements of the network to set the tone for the project. Next, selecting the appropriate type of fiber optic cable is crucial; whether it is single-mode or multi-mode fiber, the choice must be made precisely based on actual needs. Additionally, drawing detailed cabling diagrams and planning the pathways are key steps, as they help ensure that the layout of the fiber optic network is both reasonable and efficient.

Before initiating fiber optic cabling installation, thorough design planning is an indispensable step. In this process, we first need to clarify the specific requirements of the network to set the tone for the project. Next, selecting the appropriate type of fiber optic cable is crucial; whether it is single-mode or multi-mode fiber, the choice must be made precisely based on actual needs. Additionally, drawing detailed cabling diagrams and planning the pathways are key steps, as they help ensure that the layout of the fiber optic network is both reasonable and efficient.

Through meticulous design planning, we can ensure that the fiber optic network meets the expected bandwidth requirements, coverage area, and flexibility needs. Moreover, we must fully consider future expansion needs to reserve adequate space for the network's ongoing development.

2. Preparation Work

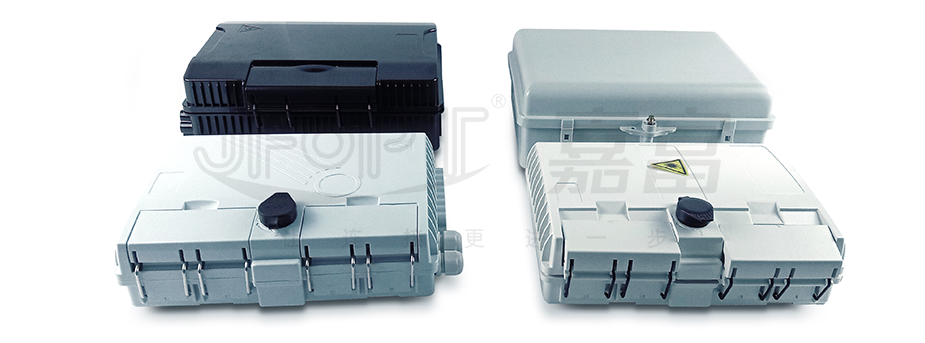

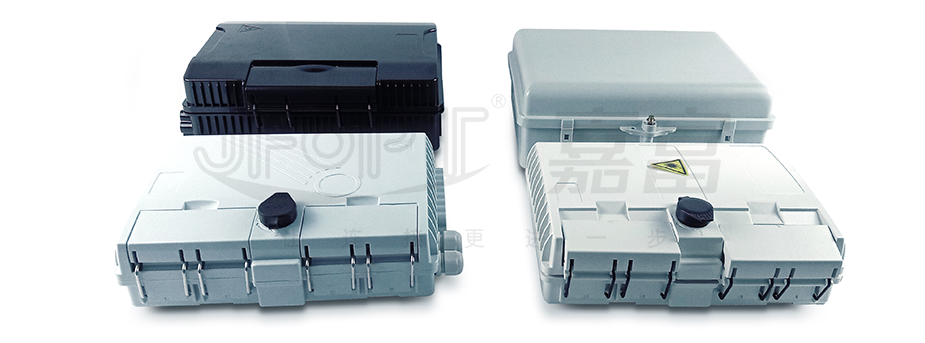

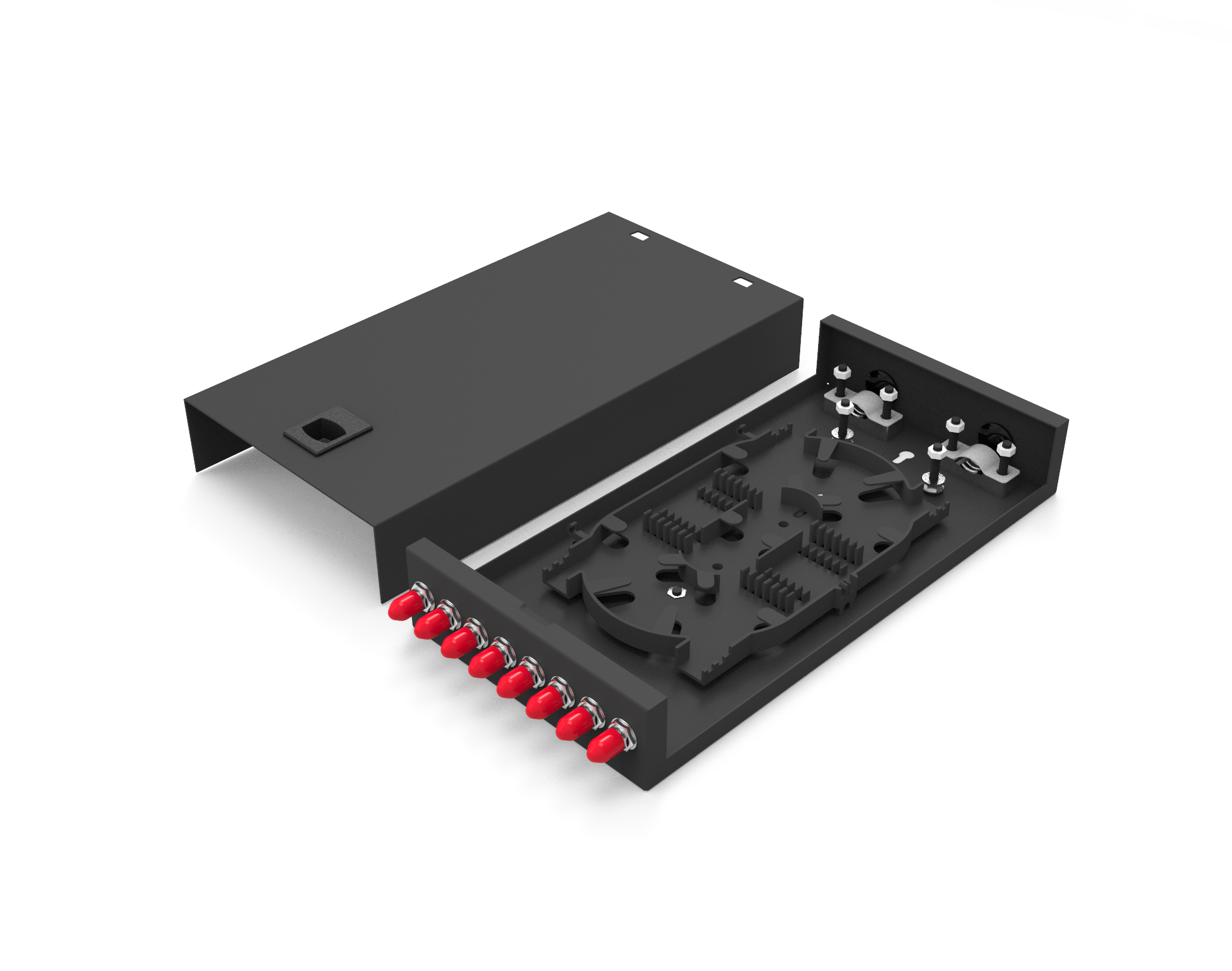

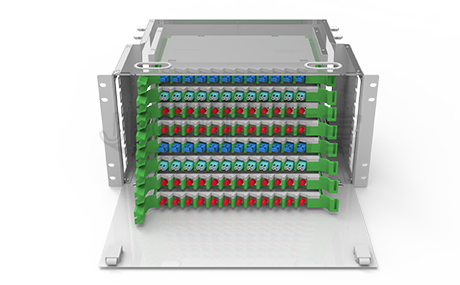

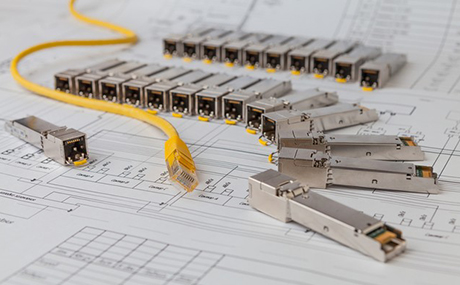

Before starting fiber optic cabling installation, the primary task is to ensure that all necessary materials and equipment are fully prepared. This includes, but is not limited to, fiber optic cables, patch panels, and fiber optic terminal boxes. Next, it is crucial to thoroughly clean the construction site to ensure that the work area is tidy and free of debris, thereby avoiding any potential obstacles or cable entanglement. Finally, we need to prepare a series of essential tools and safety equipment, such as wire strippers, fiber optic cutters, and safety gloves, to ensure a smooth installation process and the safety of the workers.

Before starting fiber optic cabling installation, the primary task is to ensure that all necessary materials and equipment are fully prepared. This includes, but is not limited to, fiber optic cables, patch panels, and fiber optic terminal boxes. Next, it is crucial to thoroughly clean the construction site to ensure that the work area is tidy and free of debris, thereby avoiding any potential obstacles or cable entanglement. Finally, we need to prepare a series of essential tools and safety equipment, such as wire strippers, fiber optic cutters, and safety gloves, to ensure a smooth installation process and the safety of the workers.

3. Cable Installation

Before commencing the cable installation process, it is imperative to clearly mark the planned cable pathways and ensure that the cabling environment is dry, clean, and free from obvious physical damage to ensure the safety and stability of the cables. Next, we will strictly adhere to the predetermined design plan to accurately lay the cables along the established pathways. During this process, we will adhere strictly to the correct bending radius and tension control principles to minimize any damage to the fibers. Additionally, to mitigate the risk of interference and conducted noise, we will pay special attention to maintaining appropriate separation between the cables and power lines.

4. Fiber Optic Connection and Testing

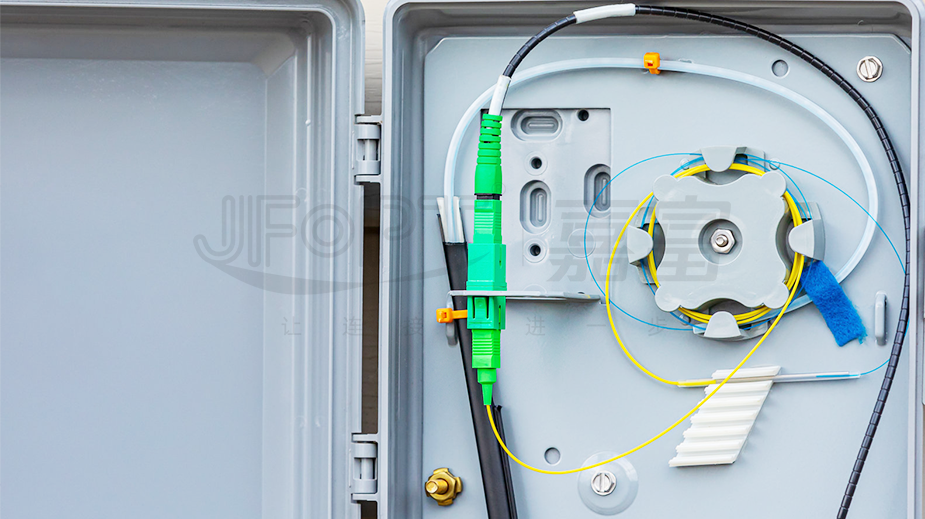

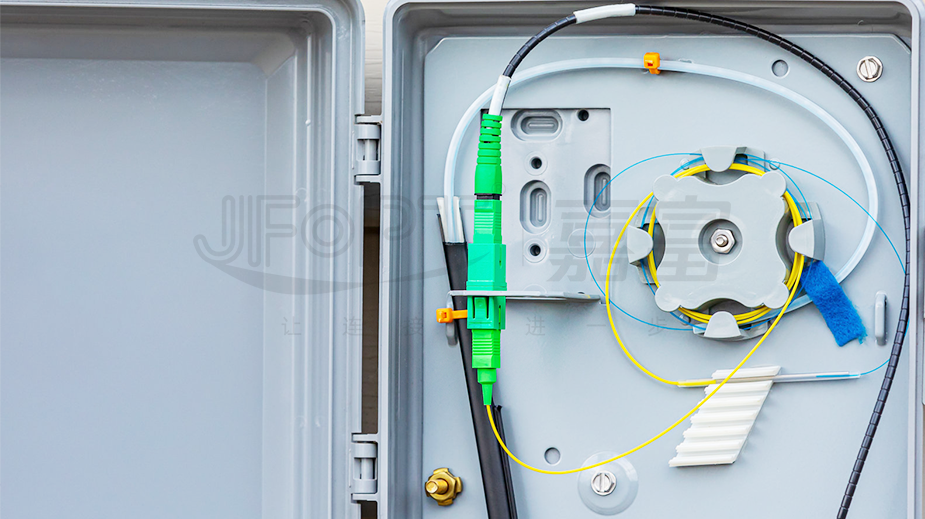

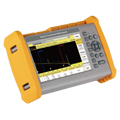

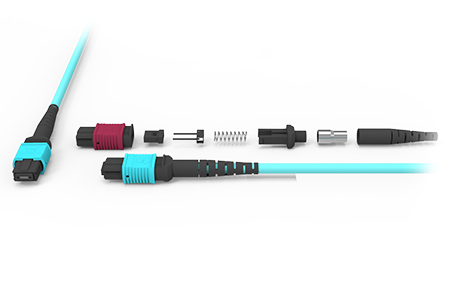

Fiber optic connection and testing undoubtedly constitute a critical phase in fiber optic cabling installation. Before proceeding with fiber optic connections, meticulous cleaning of the fiber optic ends is essential to ensure their surfaces are clean and dust-free, laying a solid foundation for high-quality connections. Subsequently, utilizing suitable fiber optic connectors and professional pairing tools, we precisely connect the fiber cables to the terminal equipment and verify the stability and reliability of the connections through insertion and removal testing. Upon completing the connections, comprehensive testing of the fiber optic links is indispensable, including attenuation, return loss, and continuity testing, aimed at ensuring the fiber optic network's performance meets the required standards, providing a solid guarantee for efficient data transmission.

5. Labeling and Documentation

After the construction is complete, labeling and documenting the fiber optic cabling are essential steps. We need to affix clear and legible labels to each connection point and device, containing detailed information such as port numbers, location details, etc., for easy identification and localization. Additionally, we will compile detailed documentation, including cabling diagrams, troubleshooting procedures, maintenance plans, and other important information, aimed at providing convenience and reference for future maintenance and management.

6. Safety and Protection of Fiber Optics

During fiber optic cabling, a series of protective measures must be taken, such as conduits, cable trays, and bridges, to ensure that the fiber optics are protected from mechanical pressure, chemical corrosion, and environmental factors. These measures not only help maintain the integrity of the cables and connectors but also prolong their lifespan, ensuring the safe and stable operation of the fiber optic network. By implementing appropriate protective measures, we can provide solid protection for fiber optic cabling, ensuring smooth and efficient data transmission.

7. Safety and Compliance

During fiber optic cabling projects, it's essential to strictly adhere to local construction and electrical safety regulations to ensure compliance with industry standards such as ANSI/TIA/EIA, ISO/IEC, and others. This is not only responsible for the safety of construction personnel but also a strong guarantee for the stability and reliability of the entire fiber optic network. Throughout the construction process, safety and protection are prioritized, with construction personnel required to wear necessary safety equipment such as gloves and goggles to prevent any potential accidents. By rigorously adhering to these standards and precautionary measures, we can ensure the smooth progress of fiber optic cabling projects while providing users with a safe, stable, and reliable fiber optic network environment.

Ann

Ann