A broken optical cable is a serious problem; it can cause communication interruptions, affecting data transmission and network services. When an optical cable breaks, swift action is needed to repair it and restore normal communication. Optical cable repair is a complex process that requires professional skills, typically performed by specialized optical cable repair companies or telecom operator personnel. If you encounter such a situation, it is best to promptly contact professionals to handle it.

Optical cable breakage is a common occurrence in the daily operations of weak current projects. So, how is a severed optical cable repaired?

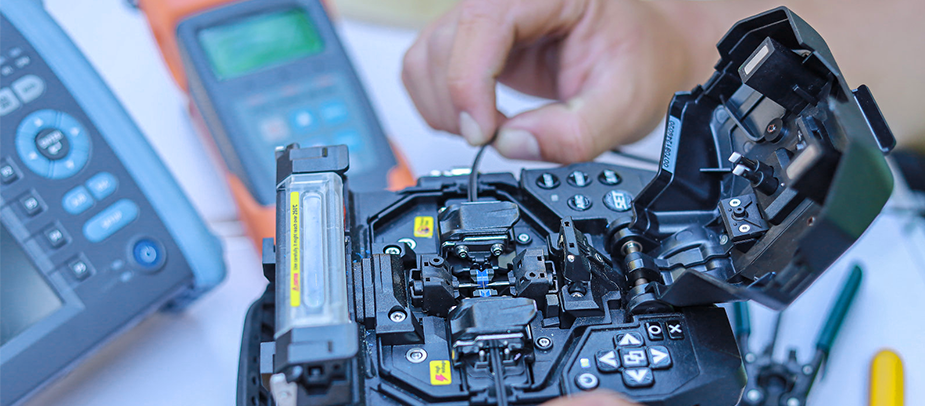

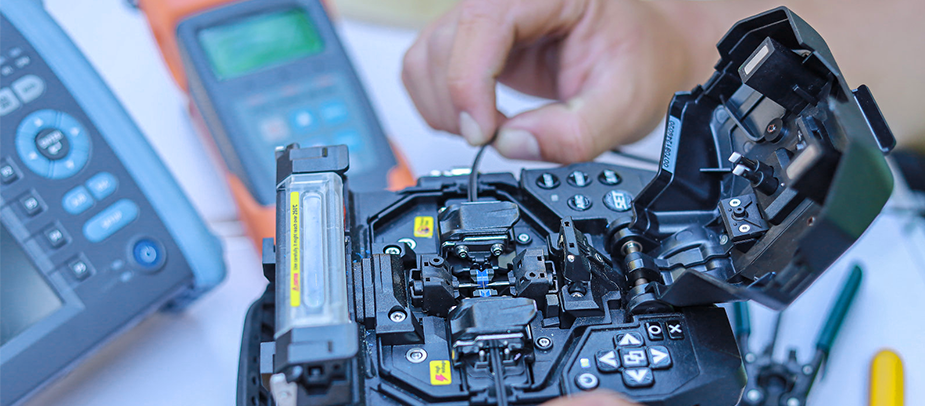

Each member of this group carries a cellphone that never turns off, ready to respond to emergencies at any moment. Their equipment is complete, including OTDRs, fusion splicers, optical power meters, splice boxes, wire ties, visual red light equipment, and other specialized tools. They are also equipped with safety helmets, reflective vests, insulated shoes, gloves, and other safety gear, fully armed and prepared to engage at any time.

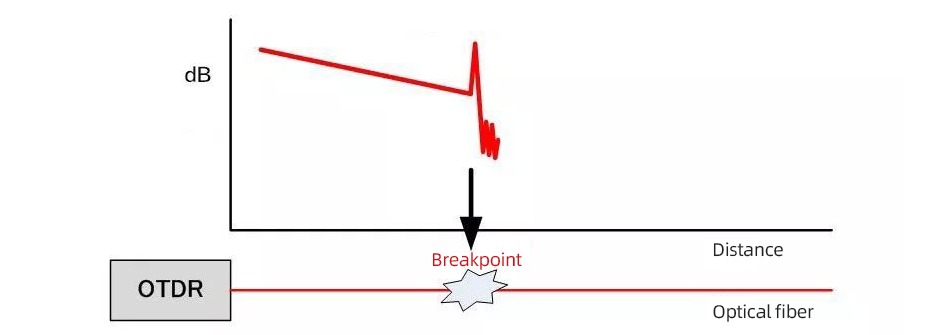

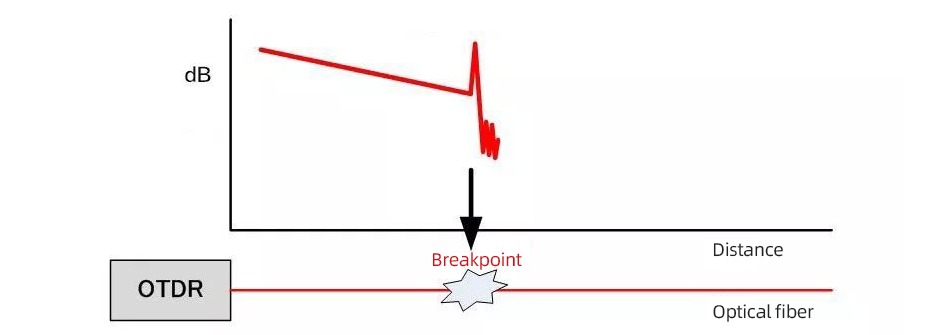

When encountering an optical cable interruption, the curve goes like this...

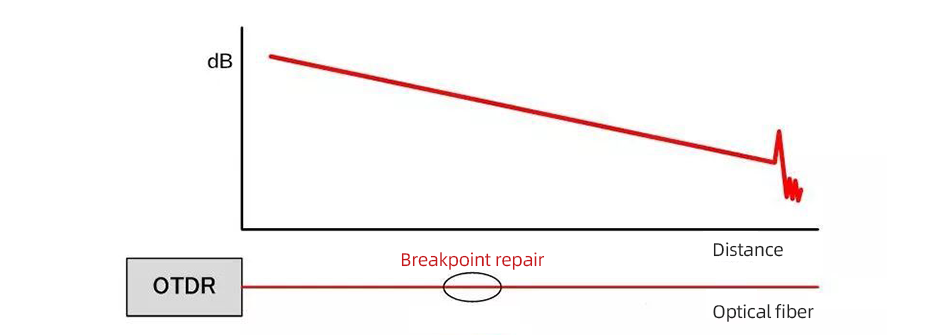

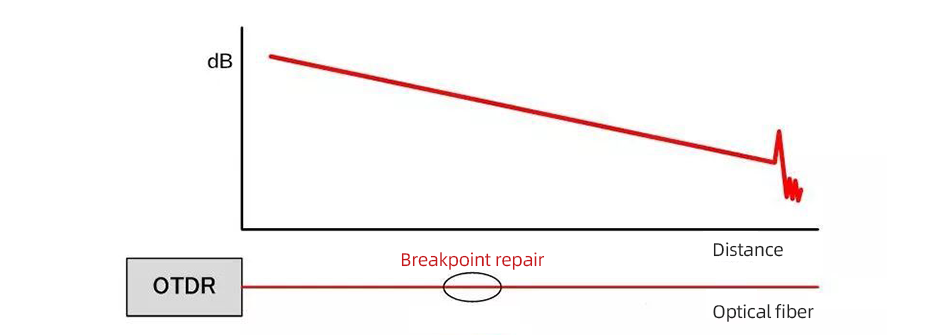

If repaired, the curve would look like this...

There are various reasons for optical cable breakage. Here are some common causes:

Natural Disasters: Earthquakes, floods, landslides, lightning strikes, storms, and other natural disasters can cause optical cable breakage, damage to splice boxes, or increased fiber fusion loss. Additionally, rodent bites and fires can also cause faults in optical cable lines.

Human Factors: These include excavation during construction, operational errors with lifting equipment, optical cable damage caused by traffic accidents, and cable theft by criminals. Furthermore, technicians may inadvertently cause human-induced faults during maintenance, installation, and other activities.

Environmental Factors: Changes in temperature, humidity, and chemical corrosion can cause optical cable aging, deformation, and cracking. Extreme weather conditions such as strong winds and ice can also lead to cable breakage. Harsh environmental conditions such as high temperatures, low temperatures, humidity, or chemically aggressive environments can easily cause the aging or deformation of optical cable materials.

Equipment Failures: Power failures, transmission equipment malfunctions, and testing instrument failures can lead to optical cable signal interruptions, attenuation, or distortion.

Cable Factors: Poor-quality optical cables, inadequate tensile strength, or insufficient cable strength can lead to breakage or damage during use. Additionally, issues like cutting corners during manufacturing, overly thin fibers, or impurities in the cable can also make optical cables prone to breakage.

Improper Installation: Improper installation, bending, stretching, or excessive pressure on optical cables can easily lead to cable breakage.

Optical cable breakage is a common occurrence in the daily operations of weak current projects. So, how is a severed optical cable repaired?

At this moment, making a grand entrance, is a group of mysterious communication heroes.

They often work quietly out of sight, whether in the still hours of three or four in the morning, deep underground in tunnels, in disaster areas ravaged by heavy rain, in remote desert regions, or on desolate construction sites. They are always steadfast in their duties.

Each member of this group carries a cellphone that never turns off, ready to respond to emergencies at any moment. Their equipment is complete, including OTDRs, fusion splicers, optical power meters, splice boxes, wire ties, visual red light equipment, and other specialized tools. They are also equipped with safety helmets, reflective vests, insulated shoes, gloves, and other safety gear, fully armed and prepared to engage at any time.

Once a fault occurs in the optical cable, this group of communication heroes will immediately receive notification.

Regardless of whether it's late at night or in the midst of a storm, they will not hesitate to bring all their equipment and rush to the scene.

Every malfunction is a command they cannot afford to fail!

As they rush to the scene, they maintain close communication with colleagues in remote data centers, jointly identifying the location of the fault.

Upon arrival, they quickly retrieve the OTDR - an optical time-domain reflectometer that precisely measures fault breakpoints using the principles of light reflection and scattering. They conduct comprehensive inspections around the fault point, swiftly determining its location.

Thus, these mysterious communication heroes, with their expertise and speed, safeguard seamless communication.

When encountering an optical cable interruption, the curve goes like this...

If repaired, the curve would look like this...

Next comes the tense yet orderly fiber optic repair work.

During the fiber optic repair process, we always adhere to the first principle: restore connectivity first, then proceed with the repair. This means that, whenever possible, we prioritize using spare fibers within the cable to restore communication in the shortest time possible, avoiding prolonged disruptions to services. Subsequently, we proceed with the replacement or repair of the broken fibers.

However, fiber optic repair is by no means an easy task. It is a rigorous test of every communication hero's physical strength, cold resistance, patience, agility, and resilience to pressure.

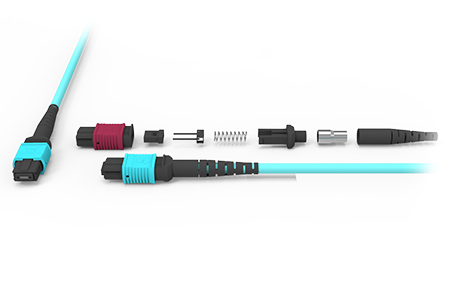

In particular, the subsequent fusion splicing of the fibers is an extremely cautious and meticulous task. Fiber optics, with threads finer than hair, are fragile yet capable of transmitting vast amounts of information. To protect them, they are encased in layers of sturdy protection, collectively forming thick optic cables.

No matter the challenges we face, we will spare no effort to ensure the smooth repair of fiber optics, safeguarding seamless communication.

When faced with a fiber optic fracture, the communication heroes act swiftly. They carefully peel away the thick protective layer of the optical cable, revealing the viscous grease inside. To prevent the grease from affecting subsequent operations, they delicately blot it dry with paper towels. Next, they gently comb out the damaged fibers and meticulously strip away the coating from the fiber cores. To ensure the quality of the fusion splice, they meticulously clean the fibers with alcohol, removing any impurities that could affect the fusion.

Once these preparations are complete, the communication heroes use professional tools to cut the fiber ends flat and smooth. Finally, they place the prepared fibers into the fusion splicer and perform precise fusion splicing operations.

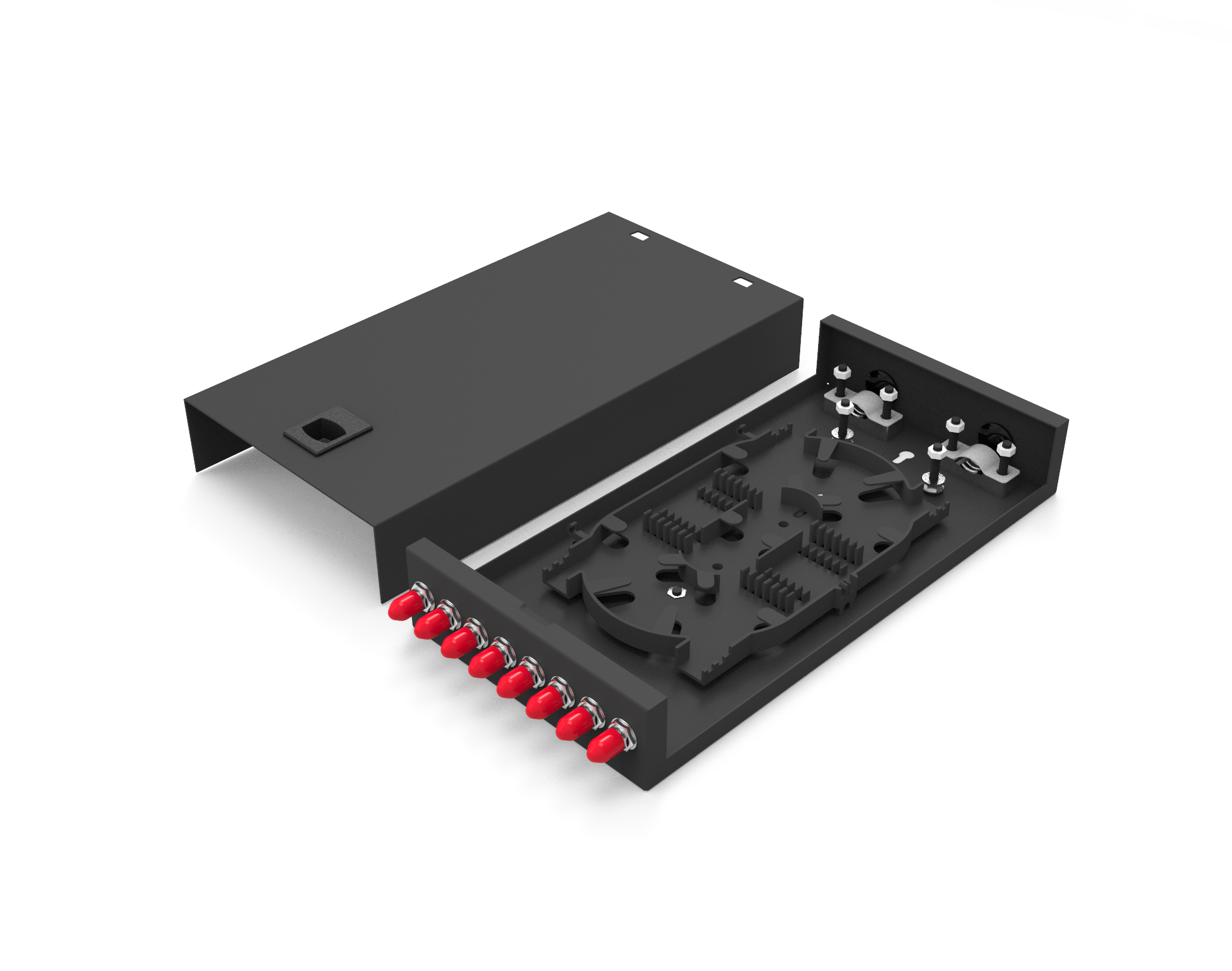

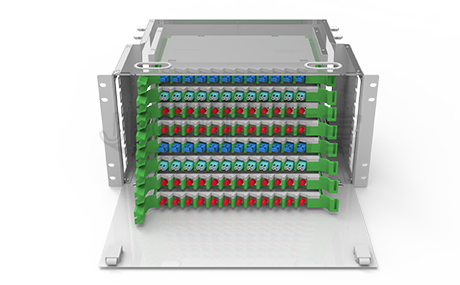

After the fusion splicing process, the communication heroes immediately apply heat shrink tubing to the fibers, carefully wrapping them one by one inside the splice box. Subsequently, they install sealant, tighten the screws, ensuring the stability and sealing of the splice box. With this, the repair work is finally completed. Each step of the operation embodies their focus and effort, all to ensure seamless communication.

Ann

Ann