Direct buried optical cable, as an important method of laying communication cables, is commonly used for long-distance communication transmission and plays a significant role in modern communication infrastructure construction. Direct buried optical cable is specially designed to be pressure-resistant, corrosion-resistant, and weather-resistant, making it suitable for long-term, safe, and stable use in soil. It typically uses double sheaths and Kevlar yarn for protection. This article can help you learn more about direct buried optical cables.

What is a direct buried optical cable?

Types of Direct Buried Optical Cables

What is a direct buried optical cable?

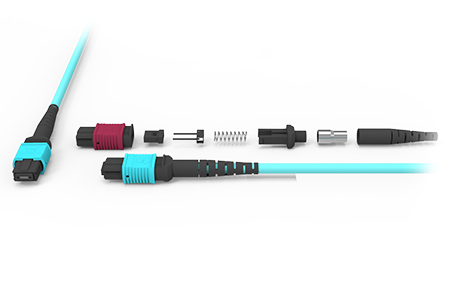

Direct buried optical cable is a reinforced optical cable that integrates steel tape or steel wire armor, specifically designed to withstand external mechanical stress and soil corrosion. It seamlessly integrates into the underground environment, performing efficiently whether manually buried in trenches or quickly laid using a vibratory plow. As a convenient choice for cable installation, the direct buried method simplifies the construction process and significantly reduces the cost burden of pipeline laying and overhead installation.

Direct buried optical cable is the ideal choice for underground construction due to its excellent mechanical strength, stable temperature adaptability, outstanding compression resistance, and flexibility. Its installation process is straightforward and fast, further enhanced by moisture barriers made from coated aluminum tape (APL) and waterproofing with coated steel tape (PSP), along with water-blocking materials designed specifically for underground environments. These features collectively ensure the long-term stable operation of the optical cable, facilitating seamless information transmission.

Types of Direct Buried Optical Cables

There are several types of direct buried optical cables available on the market. Some of the most commonly used are GYTA53, GYXTW53, and GYFTY53.

GYTA53 Optical Cable: A masterpiece of outdoor communication that integrates dual sheaths, dual armor, and stranded loose tube technology. Its unique loose tube stranded design provides ample secondary excess length for the optical fibers, ensuring they remain stress-free and can move freely within the tube even under longitudinal stress. The outer corrugated steel tape armor and dual polyethylene (PE) sheaths create an impenetrable protective barrier, offering excellent compression resistance and effective protection against rodent damage. Additionally, the built-in metal strength members enhance the cable’s strain performance. Whether buried directly underground or laid in ducts, the GYTA53 optical cable demonstrates remarkable adaptability and stability, making it an indispensable choice for modern communication network construction.

GYXTW53 Optical Cable: This central loose tube cable integrates dual steel tape and dual PE sheaths, designed for harsh environments. Its unique full-section water-blocking structure forms an impenetrable barrier against water and moisture, ensuring seamless information transmission. The special grease-filled loose tube acts as a protective layer for the crucial optical fibers, shielding them from external harm. Inside the cable, two parallel steel wires enhance its tensile and side pressure resistance while maintaining a small diameter and lightweight profile. With excellent bending performance, the GYXTW53 can easily navigate narrow spaces and adapt to complex terrains, making it an indispensable high-performance cable in modern communication construction.

GYFTY53 Optical Cable: A masterpiece of outdoor communication that merges innovative technology with environmental consciousness. It features a non-metallic strength member design combined with loose tube layer stranding technology. The inner layer is coated with a polyethylene sheath, while the outer layer consists of non-metallic fiber reinforcement and low-smoke, zero-halogen (LSZH) materials, demonstrating excellent outdoor adaptability. The cable's full-section water-blocking structure ensures superior waterproof and moisture-proof performance, safeguarding information transmission. The loose tube is filled with specialized grease, providing meticulous protection for the optical fibers and glass yarn, while also granting the cable outstanding tensile strength and resistance to rodent damage. Notably, the non-metallic strength member design makes it an ideal choice for communication infrastructure in high lightning-prone areas, ensuring communication safety while being environmentally friendly.

Advantages

High Reliability: Direct buried optical cables offer excellent waterproof, corrosion-resistant, and rodent-resistant properties, ensuring a long service life and low failure rate when used underground.

Easy Maintenance: Once installed, the cables are less affected by external environmental factors, making routine maintenance relatively simple.

Superior Transmission Performance: Optical fibers have low signal loss, long transmission distances, and high bandwidth, making them ideal for high-speed, high-capacity data transmission.

Disadvantages

Complex Installation: Installing direct buried optical cables requires trench excavation and earthworks, making the process complex and costly.

Difficult Fault Location: In the event of a fault, locating and repairing the issue is challenging and requires specialized equipment and technicians.

Application Areas

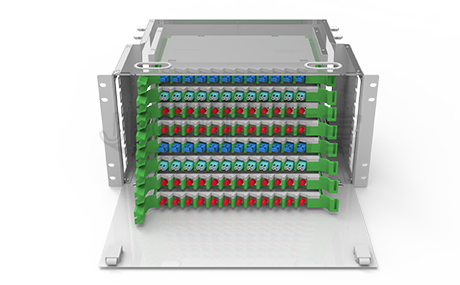

Direct buried optical cables are widely used in subways, tunnels, long-distance communication, inter-office communication networks, core networks, metropolitan area networks (MAN), local area networks (LAN), outdoor access networks, telecommunications, video and data transmission, and cable television.

Ann

Ann