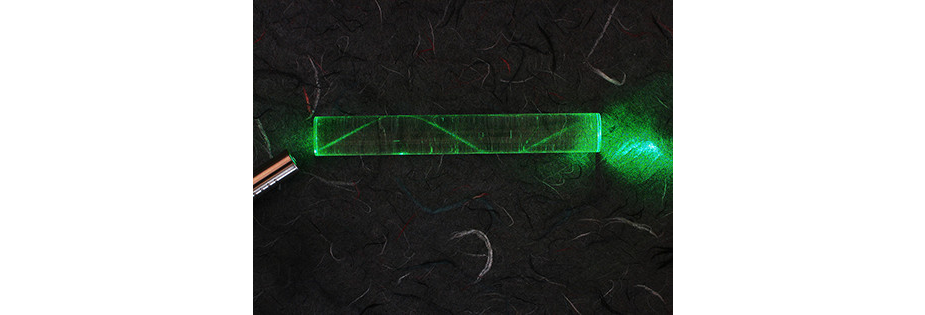

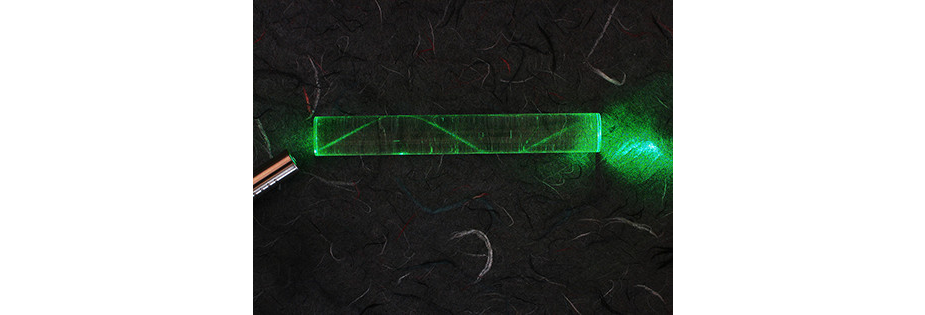

If you have ever used or are currently using fiber optic sensing equipment, you are likely aware of the importance of fiber optic cleaning. Every engineer emphasizes this point during training. As the pace of fiber-to-the-home projects accelerates and 5G communication technology becomes commercially available this year, the demand for fiber optic cables continues to grow, and the issue of fiber optic cleaning is receiving increasing attention. Even though optical fibers come with dust caps from the factory, is it still necessary to clean the fiber end faces? The answer is: absolutely. What may seem like a simple operation actually involves a wealth of knowledge.

What is an optical fiber? Optical fiber, short for optical fiber conductor, is mainly made of glass or plastic. Although as thin as a hair, it serves as a medium for transmitting light signals. In the optical communication industry, applications like patch cords, drop cables, and trunk cables are quite common, and their core component is the optical fiber. Despite the durability of the fiber material, it is highly susceptible to contamination. If the end face of the fiber gets contaminated with dust, oil, or scratches from clothing, the quality of light signal transmission can significantly degrade, increasing loss. In severe cases, it can even lead to the failure of the entire optical network system.

1. Why is fiber optic cleaning crucial?

2. Common Fiber Optic Cleaning Tools and Methods of Use

Figure 3 How to use a fiber optic cleaner

3. Special Reminders

What is an optical fiber? Optical fiber, short for optical fiber conductor, is mainly made of glass or plastic. Although as thin as a hair, it serves as a medium for transmitting light signals. In the optical communication industry, applications like patch cords, drop cables, and trunk cables are quite common, and their core component is the optical fiber. Despite the durability of the fiber material, it is highly susceptible to contamination. If the end face of the fiber gets contaminated with dust, oil, or scratches from clothing, the quality of light signal transmission can significantly degrade, increasing loss. In severe cases, it can even lead to the failure of the entire optical network system.

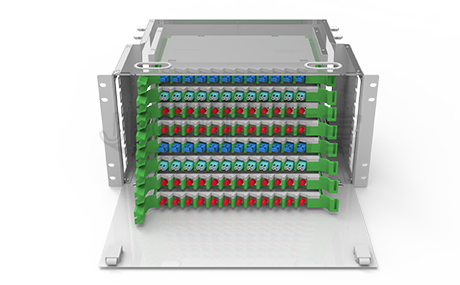

Fiber optic cleaning is a common issue in the fiber optic communication industry. It is said that nearly 80% of fiber optic link failures can be improved by cleaning the fiber end face. Similarly, the fiber optic sensing industry faces comparable issues; the vast majority of after-sales problems are due to dirty or damaged fiber end faces, leading to signal attenuation or transmission failure, which affects sensing measurement results and can even halt measurements entirely. If you understand the working principles of optical fibers and the structure of the end face, you will grasp why fiber optic cleaning is so important.

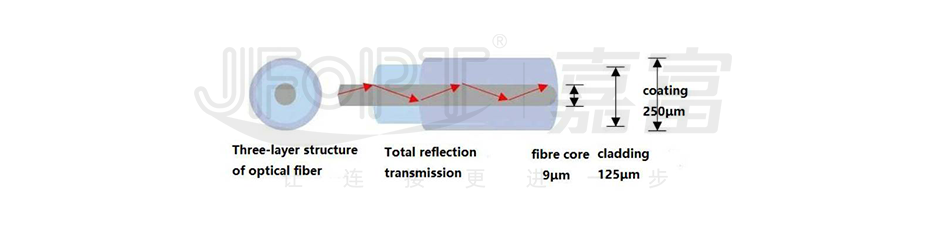

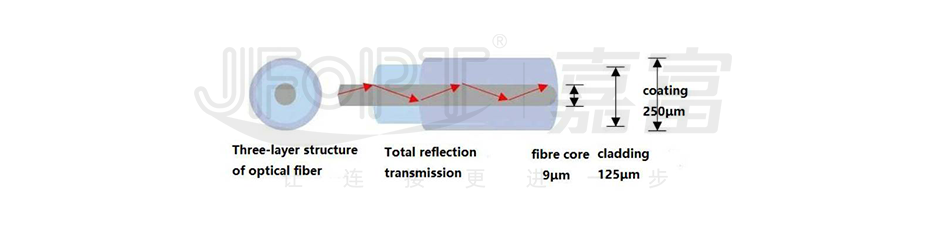

Typically, bare fiber consists of a core, cladding, and coating layer, where the core and cladding are made of silica with different refractive indices, with the core having a higher refractive index than the cladding. When the incident light meets the conditions for total internal reflection within the fiber, the light signal can propagate through the fiber.

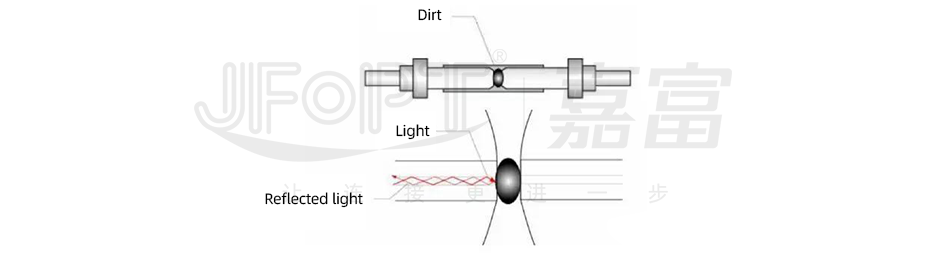

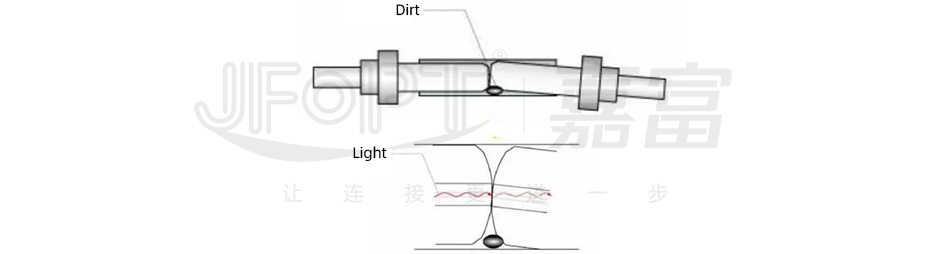

Figure 1 Single-mode optical fiber structure and working principle

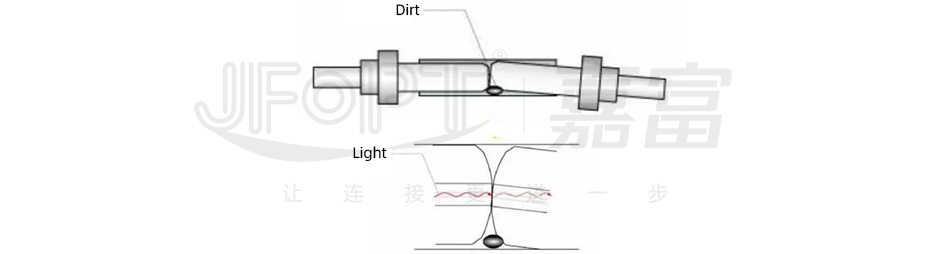

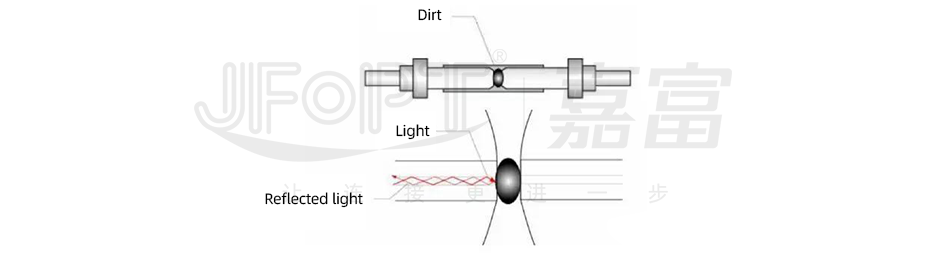

The attenuation coefficient of standard single-mode fiber at a wavelength of 1550 nm is about 0.2 dB/km, resulting in very low transmission loss. However, since the light signal primarily travels through the fiber core, which has a diameter of only about 9 μm (approximately 1/10th the diameter of a human hair), any dirt or damage on the fiber end face can hinder the smooth transmission of the light signal and increase reflection. This leads to high reflections in the link, as well as decreased light power and signal attenuation, issues that can be analyzed using an OFDR curve. When this occurs, the testing results will be affected.

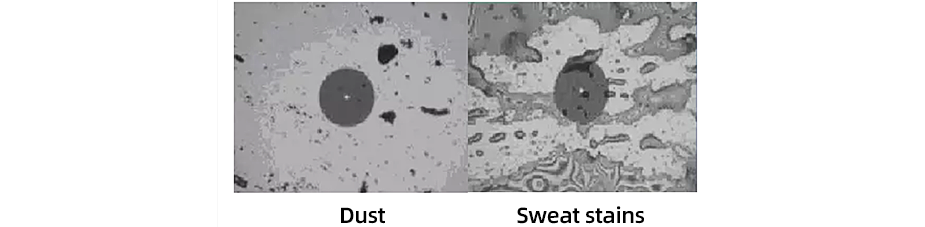

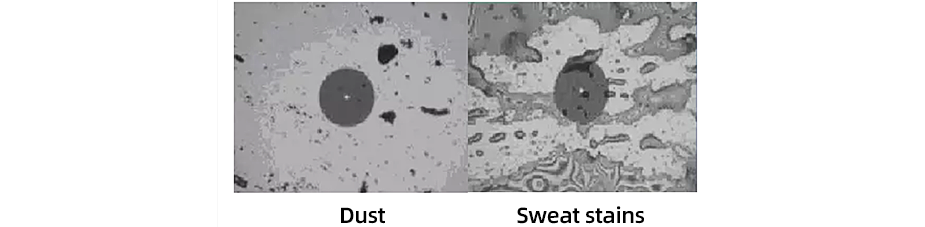

A greater risk of a dirty fiber end face is that when dust, especially hard particles, adheres to the fiber connector, it can damage the fiber end face when mated with another connector. If the fiber connector inside the equipment is damaged, the equipment typically needs to be sent back to the manufacturer for repair.

Figure 2: Dirt or damage on the end surface

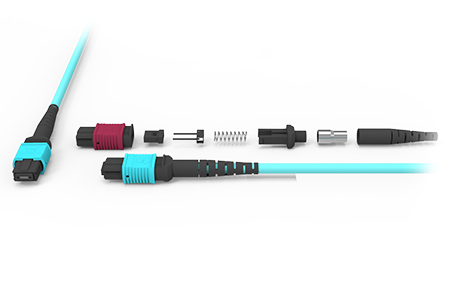

1) Fiber Optic Cleaner

The fiber optic cleaner contains high-quality lint-free fiber cloth, precisely designed for the meticulous cleaning of fiber end faces. It effectively removes dust, oil, and various tiny particles from the end face without causing any damage or scratches. This tool is suitable for a wide range of fiber connectors, including but not limited to FC/APC, FC/PC, LC/UPC, and SC/APC, meeting the cleaning needs of different scenarios.

When using the fiber optic cleaner, refer to the simple steps shown in Figure 3 to easily complete the cleaning task. Additionally, considering cleaning efficiency and long-term use, the fiber optic cleaner is designed with a replaceable cleaning reel function. After a period of use, the cleaning cloth can be conveniently replaced with a new reel, ensuring optimal cleaning performance each time and extending the lifespan of the fiber and the entire optical communication system.

Figure 3 How to use a fiber optic cleaner

2) Fiber Optic Cleaning Pen

The fiber optic cleaning pen is a versatile tool designed for the maintenance of fiber optic connectors. Its unique design not only cleans the surface of the connectors but also reaches deep into equipment interfaces to meticulously clean the fiber end faces, ensuring an unobstructed light signal transmission path. As shown in the figure, the fiber optic cleaning pen demonstrates its flexibility and efficiency during operation.

To ensure optimal cleaning results and compatibility, users should select the appropriate fiber optic cleaning pen based on the type of fiber connectors they are using, such as FC, LC, SC, etc.

3) Lint-Free Paper

In addition to professional fiber optic cleaners, users can also choose to use lint-free paper as a cleaning tool for fiber optic connectors, providing reliable cleaning results. With its excellent absorption capabilities, lint-free paper effectively removes dust, oil, and other contaminants from fiber connectors, offering functionality comparable to fiber optic cleaners. However, to ensure optimal cleaning results and avoid cross-contamination, users should pay special attention to the following points: first, frequently replace the lint-free paper to avoid using paper that has already absorbed contaminants; second, avoid wiping the same area repeatedly, as this may transfer removed contaminants back onto the fiber connector, causing secondary contamination.

4) Alcohol Wipes

Although some users opt to use alcohol wipes for cleaning fiber optic connectors, it is important to note that most commercially available alcohol wipes contain 75% alcohol. While this concentration has some cleaning capability, it may also contain trace impurities. Compared to professional fiber optic cleaners and lint-free paper, the cleaning effectiveness of alcohol wipes may be slightly inferior, as they might not thoroughly remove all contaminants from fiber connectors. There are also potential risks, such as alcohol residue potentially affecting fiber performance or accelerating fiber aging. Therefore, it is generally recommended to prioritize the use of the more professional and efficient cleaning methods mentioned above.

1)When storing equipment and fiber optic patch cords, always cover them with dust caps. In harsh environments, additional protective measures should be taken.

2)Regardless of the situation, if a fiber optic connector is unplugged from the equipment, it must be cleaned before being reinserted.

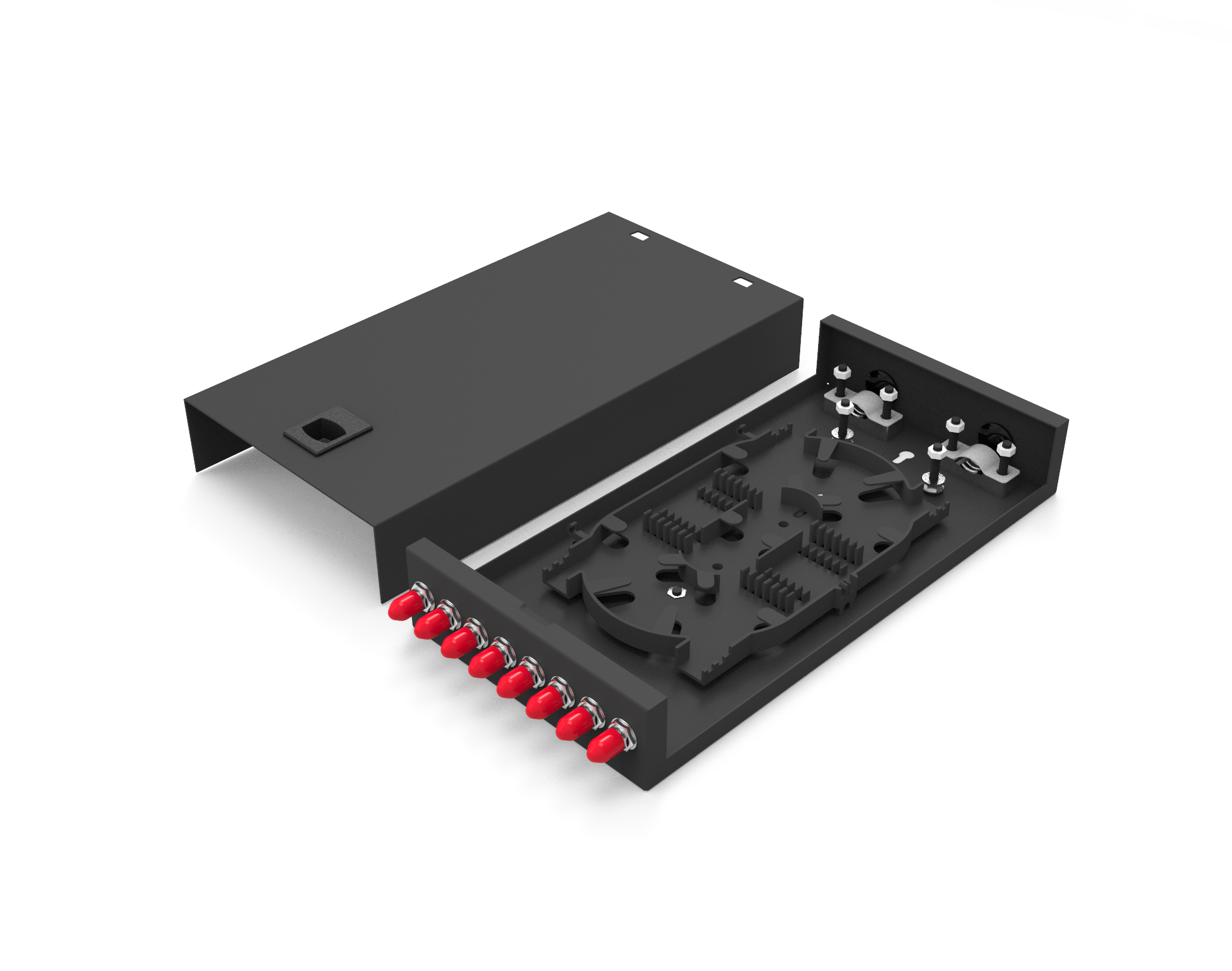

3)When making fiber optic connections in a lab environment, avoid directly connecting fiber optic connectors to equipment ports to reduce the risk of contamination. It is recommended to use clean, dust-free fiber optic patch cords and connect them via a flange adapter. This not only protects the equipment ports from contamination but also allows for easy cleaning and maintenance of the connection points, ensuring smooth and stable light signal transmission.

Ann

Ann