The fast field optical connector is designed to be assembled in the installation field. With the development of FTTH, the requirements for the simplicity and efficiency of optical fiber termination are getting higher and higher.

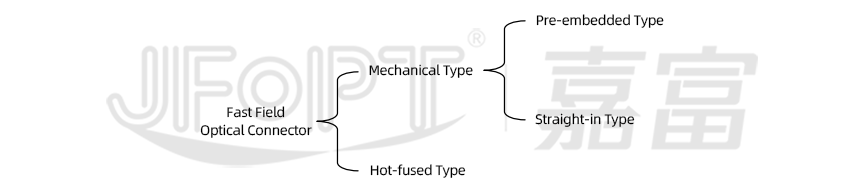

Types of Fast Field Connector

The fast field connector is generally divided into two categories: mechanical type and hot-fused type, of which mechanical type is divided into pre-embedded type and straight-in type.

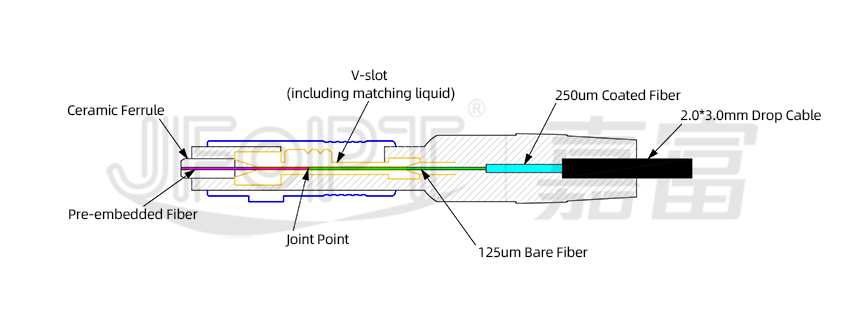

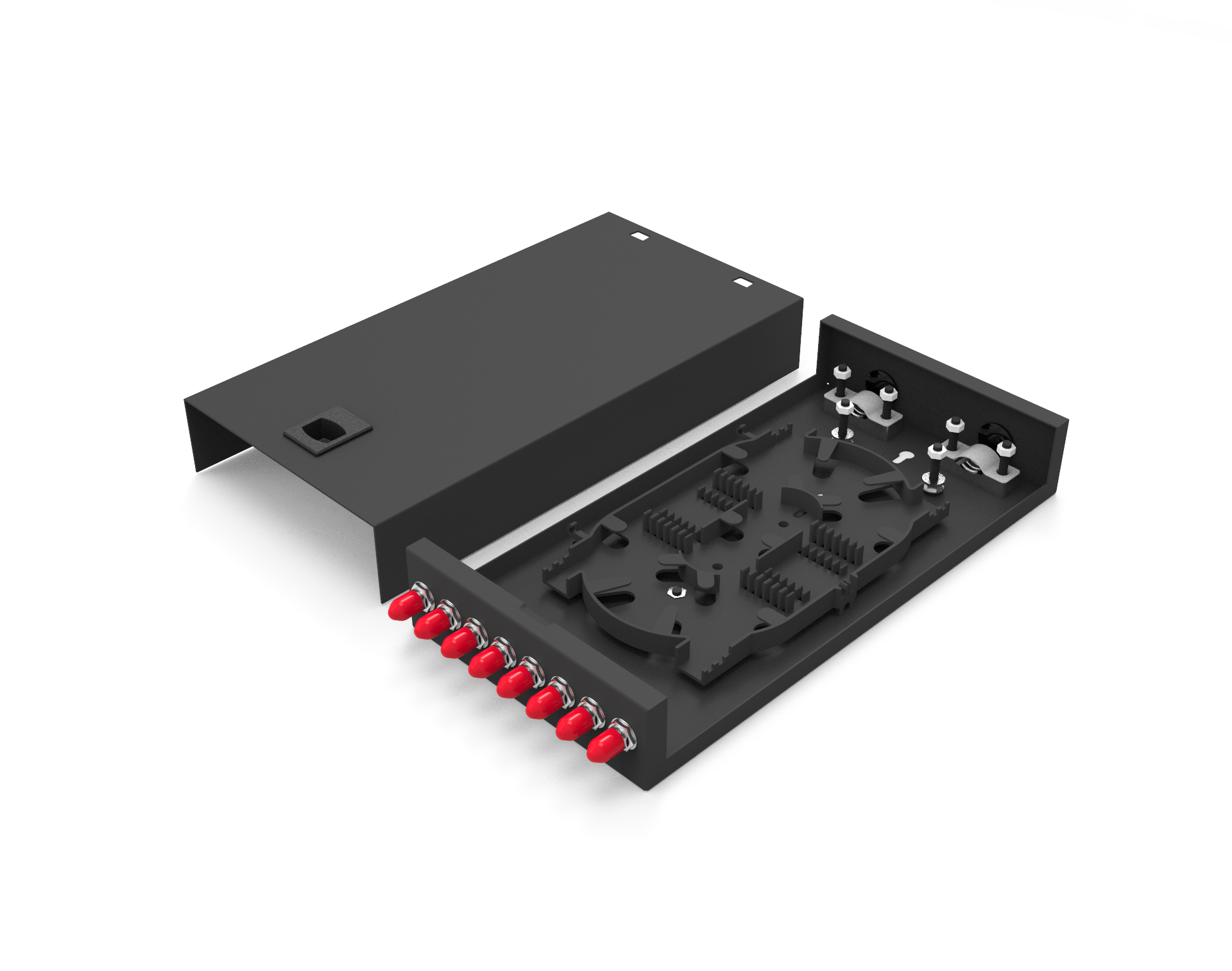

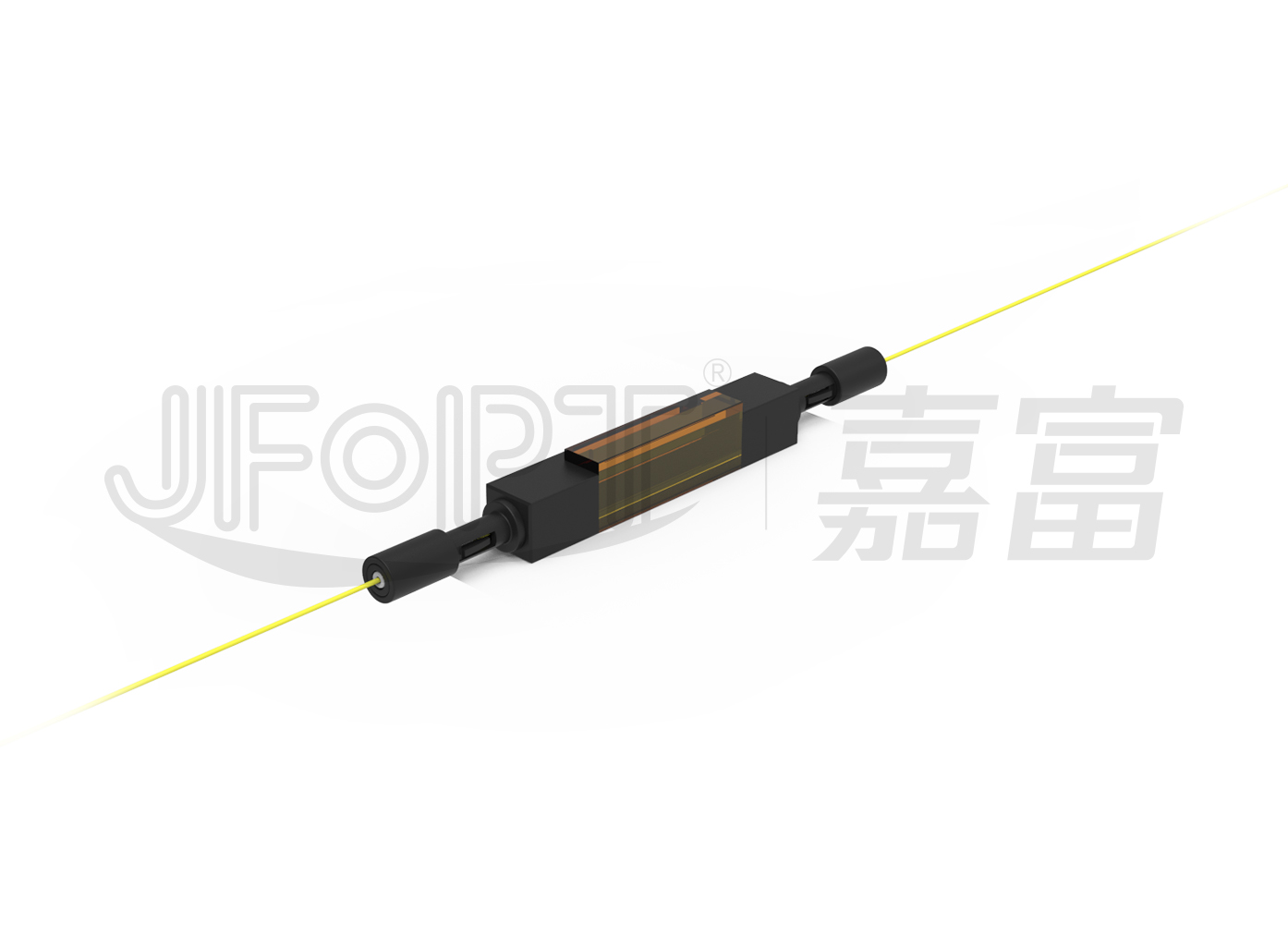

Pre-embedded Mechanical Fast Connector

A section of optical fiber is pre-embedded in the ferrule and the V-slot inside the mechanical fast connector. During construction, the fiber of the fiber optic cable that needs to be quickly terminated is put into the V-slot, to aligned with pre-embedded fiber in the V-slot.

The available types are SC (UPC, APC), FC (UPC, APC) and LC (UPC, APC).

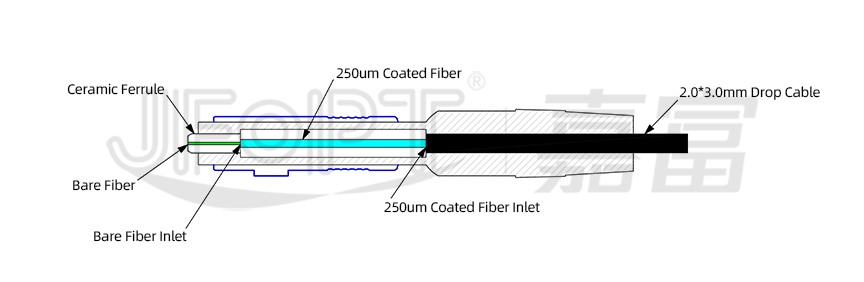

Straight-in Mechanical Fast Connector

The stripped and cut-off fiber is inserted directly from the end of the straight-in connector body to the top of the ferrule without other connection points inside.

There are SC (UPC), FC (UPC), LC (UPC) types of straight-in mechanical connections.

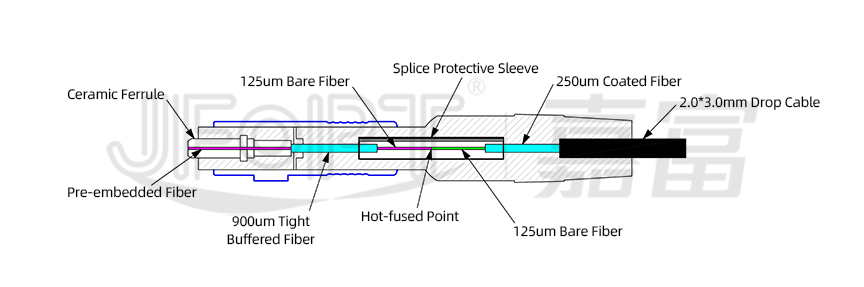

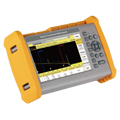

Hot-fused Fast Connector

There is pre-embedded fiber in the hot-fused fast connector too. The pre-embedded fiber will be spliced with the target fiber in the connector, to make the connector equivalent to a pigtail, but the fusion point is protected to the connector.

During the installation, to remove the boot of the connector, and to strip and cut the exposed tight-sleeved optical fiber, and then to splice it with the target fiber in the optic cable with a fiber fusion splicer.

The available types are SC (UPC, APC) and FC (UPC, APC).

Advantages and disadvantages

From the above introductions, it can tell the advantages and disadvantages of different fast connectors:

Hot-fused fast connector is still needed to be spliced to join like the traditional way of fiber splicing. Therefore, it has not been greatly improved in the convenience of operation, so it is rarely installed at present.

For straight-through quick-connection, since the optical fiber is directly inserted into the top of the ferrule, the operation requirements must be very strict for the fiber cutting, otherwise the optical performance will be greatly affected. In addition, the matching of the inner diameter of the ferrule and the outer diameter of the optical fiber is very hard. Once the inner diameter of the ferrule is too large or too small, the optical fiber will shake in the ferrule or cannot penetrate at all. Therefore, there are fewer applications either now.

Pre-embedded mechanical connector solves the problem of straight-in connector. A piece of optical fiber is pre-embedded from the ferrule to the connector body. This piece of optical fiber and ceramic ferrule have been pre-processed in the factory, to guarantee its optical performance. Coupled with the matching liquid in V-slot, the assembly requirement is not such strict. Moreover, it does not require any hot splicing operation, just simple tools needed for field operation.

It can be seen from the above introduction that compared with the other fast connects, the pre-embedded one has all the advantages of simple operation for time saving; simple tools required for easy field installation. Therefore, it has become the most popular choice at the end of the FTTH project.

Ann

Ann