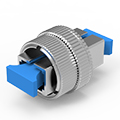

MPO and MTP fiber connectors are among the common interfaces, sharing similarities as well as notable differences. Let's start with definitions.

1. MPO and MTP Fiber Connectors

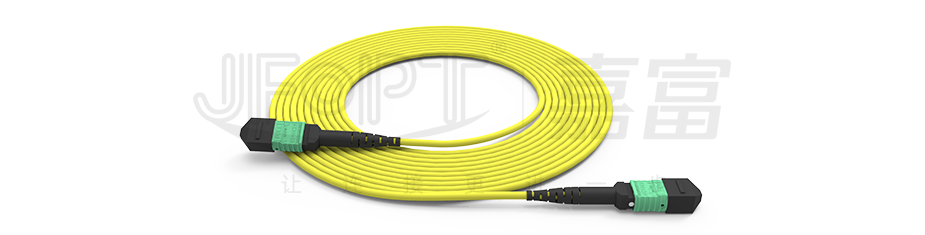

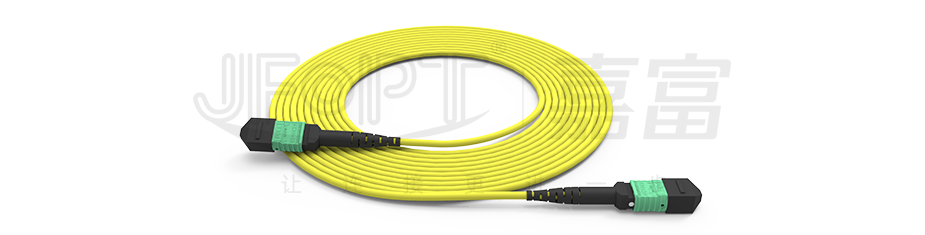

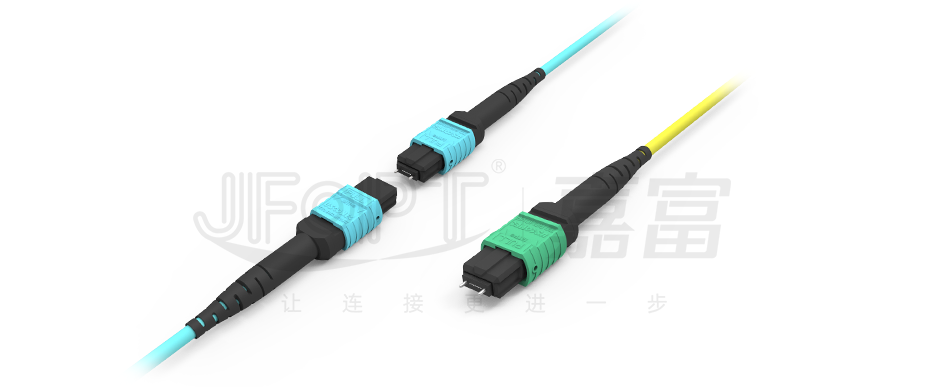

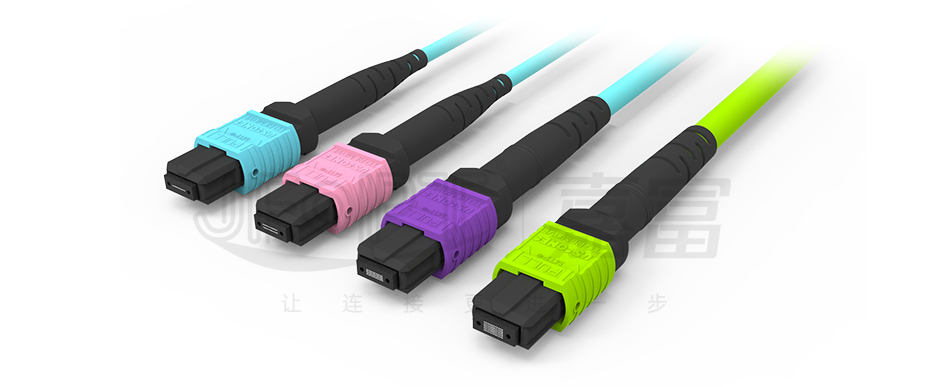

The MTP connector is a high-performance version of the MPO connector.

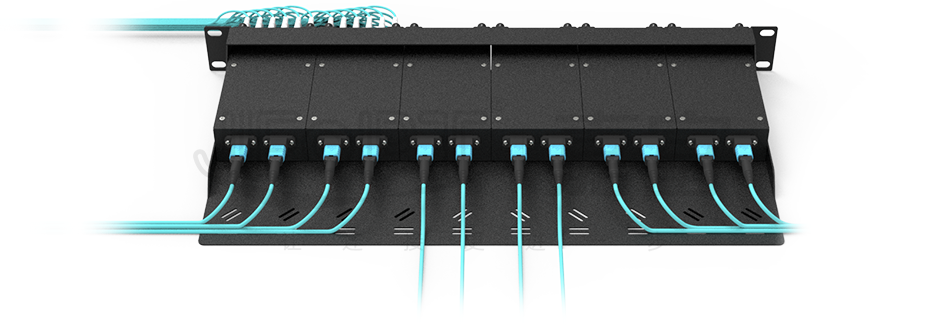

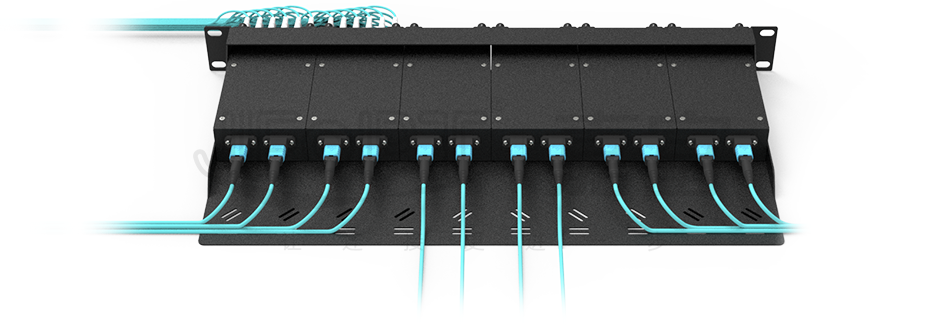

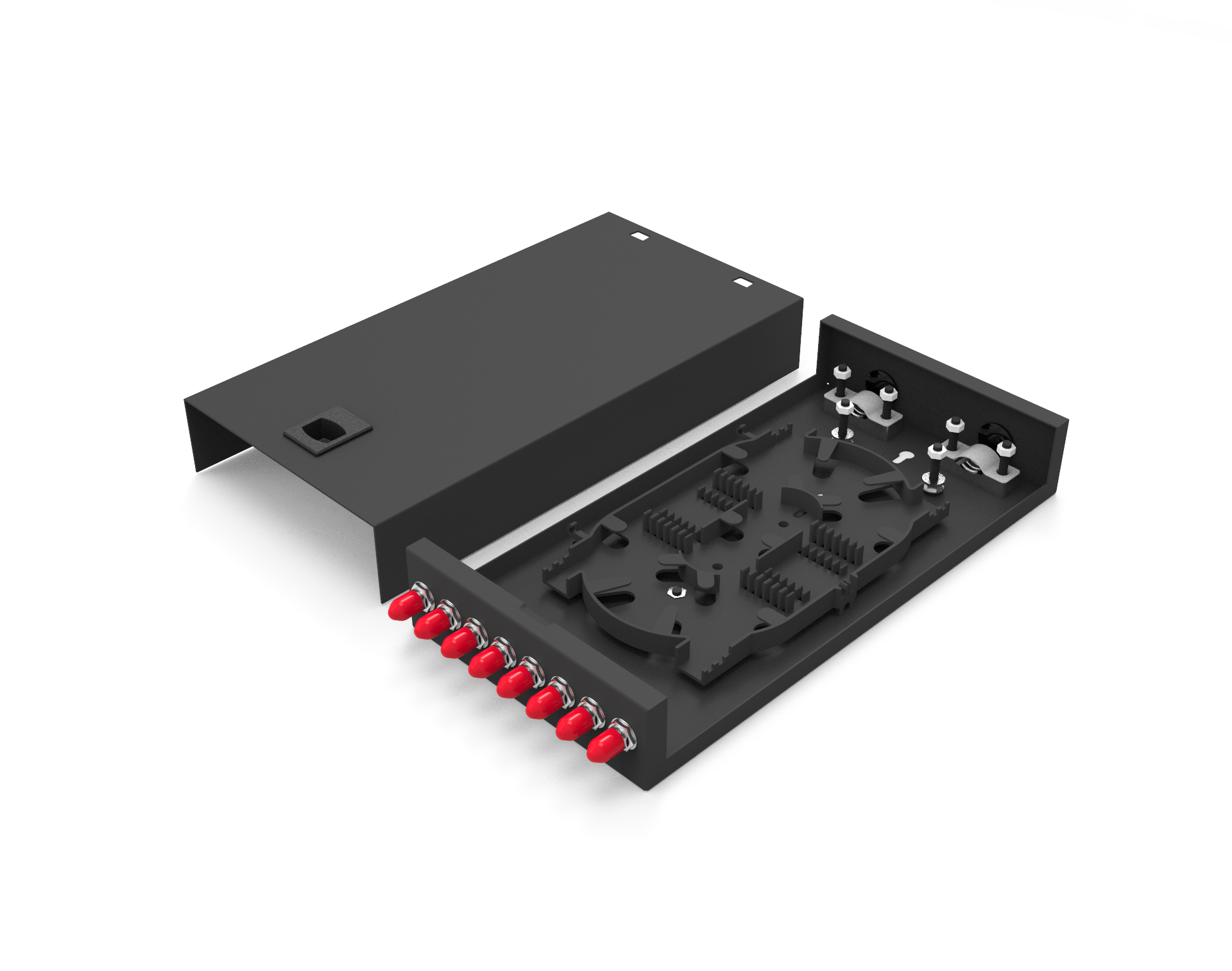

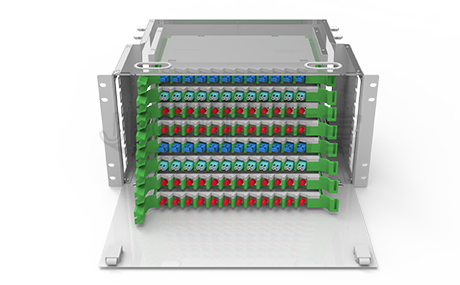

Fiber patch panel, MTP fiber modular high-density fiber distribution box.

2. What areas does MTP optimize compared to the MPO connector?

MPO stands for Multi-fiber Push On, which is the abbreviation for the first-generation multi-fiber optic connector designed by Japan's NTT Corporation. Its primary industrial standard is IEC-61754-7, while the national standard in China is YD/T1272.5-2009, and the American standard is EIA/TIA-604-5.

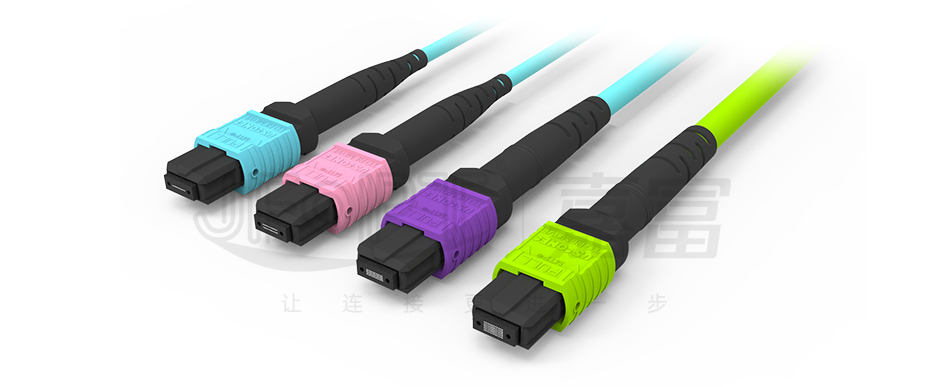

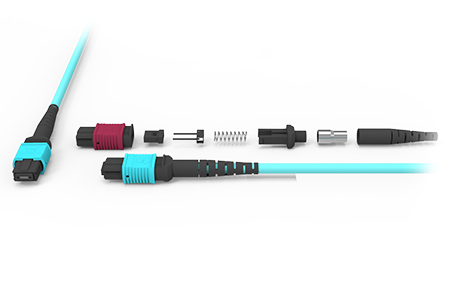

MTP stands for Multi-fiber Termination Push-on, which is a trademark registered by the US Conec company for its MPO connectors. Through innovative design, the MTP connector enhances the MPO connector with its own patented protection, offering superior mechanical and optical performance. Therefore, the MTP connector is essentially an MPO connector, fully compliant with all professional standards for MPO connectors.

The MTP connector is a high-performance version of the MPO connector.

Fiber patch panel, MTP fiber modular high-density fiber distribution box.

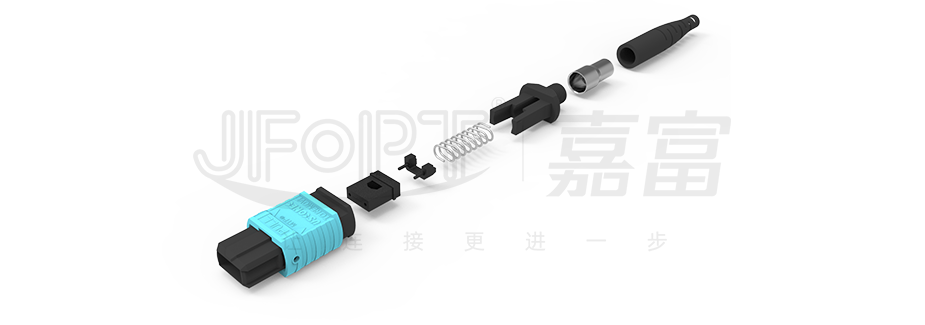

●The MTP connector utilizes stainless steel elliptical guide pins, enhancing alignment accuracy and reducing guide hole wear. In contrast, traditional MPO connectors have guide pins that, despite being chamfered, can still be sharp, leading to cracking or damage near the guide hole due to repeated insertions and removals, thus affecting connector insertion loss stability.

●The spring design of MTP fiber connectors adopts an elliptical cross-section, maximizing adaptation to the ribbon gap of multi-core ribbon fibers, effectively preventing fiber damage. Its unconventional design reduces fiber damage during insertion by spring movement and fixes the spring in the groove on the fixing clamp, ensuring the spring force is centered.

●MTP connectors incorporate guide pin retention clips to effectively prevent guide pin loss.

●The outer shell of the MTP connector is detachable, bringing multiple benefits: facilitating rework grinding of MT ferrules during production to ensure performance is not compromised; facilitating adjustment of MTP connector polarity, allowing flexible changes after production assembly; and facilitating interference checks during ferrule assembly.

●MTP connectors allow MT ferrules to float within the outer shell, enhancing mechanical performance. This means that when two MT ferrules are mated, external forces do not change the physical contact of the two end faces, maximizing optical performance.

Ann

Ann